DC01-10-Casting product valve button

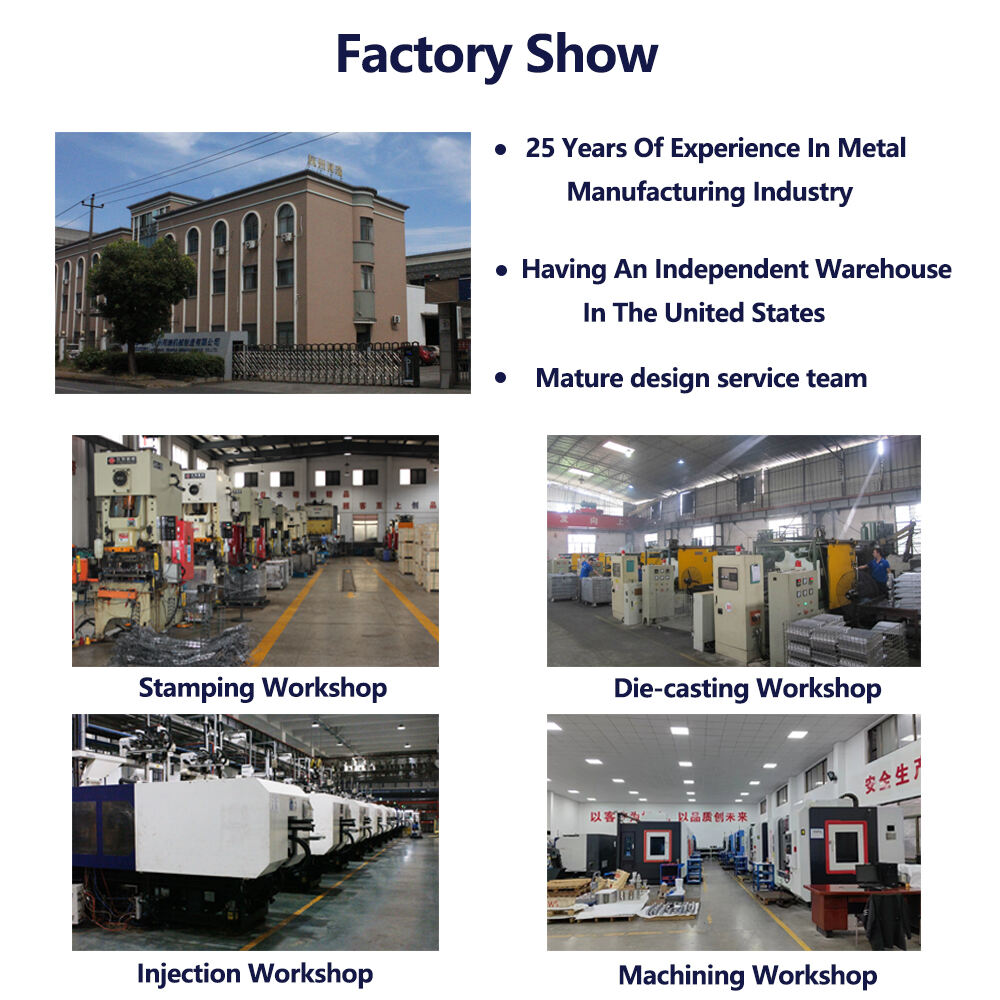

We specialize in precision die casting and CNC machining, with a professional design and production team dedicated to providing high-quality, high-precision metal component solutions. Leveraging advanced die casting processes and CNC machining centers, we offer one-stop services from blank die casting to precision machining, serving automotive parts, white goods, and other industrial sectors.

- Overview

- Recommended Products

-

Materials: Primarily utilizes Aluminum Alloy 6061-T6 for its excellent strength-to-weight ratio, machinability, and corrosion resistance—ideal for the part’s exposure to manual handling, cyclic actuation, and industrial environments. Optional materials include Zinc Alloy ZA27 (for cost-sensitive applications), Magnesium Alloy AZ91D (for ultra-lightweight designs), or Brass C36000 (for aesthetic enhancement). All materials undergo tensile strength testing (≥310 MPa for 6061-T6) and hardness verification (≥95 HB for 6061-T6).

-

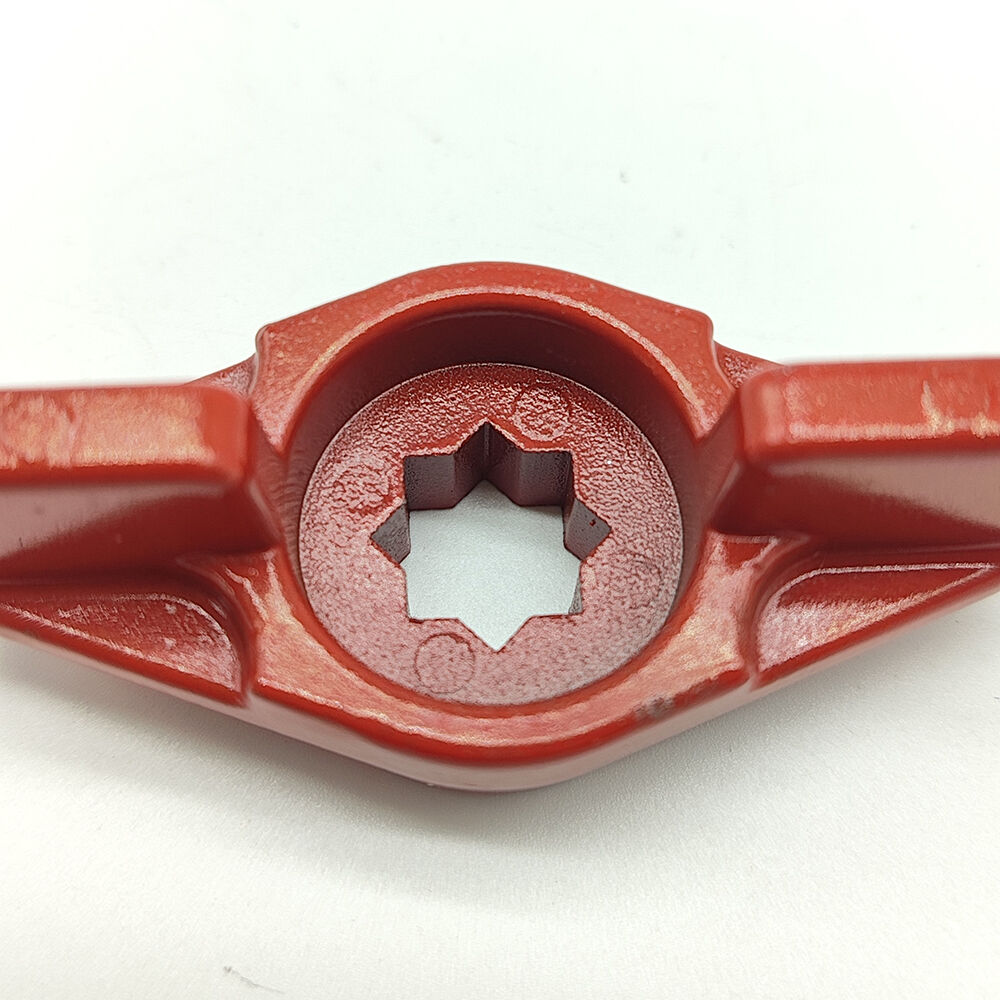

Production Process: Combines high-pressure die casting (HPDC) to form the part’s complex near-net-shape geometry (including the ergonomic levers and star-shaped drive interface visible in the images) with 3-axis CNC machining for precision feature refinement. The die casting process achieves dimensional tolerances of ±0.15mm, while CNC machining controls critical features within ±0.03mm. Fully automated production lines integrate these processes, with in-line torque testing to verify actuation reliability.

-

Surface Treatment: Supports Powder Coating (for vibrant color identification and corrosion protection), anodizing (for wear resistance), or electroplating (for aesthetic enhancement and conductivity). All surface treatments undergo salt spray testing (≥1,000 hours for powder-coated surfaces) and abrasion resistance testing (≥2,000 cycles for manual handling applications).

-

Mold Development Cycle: 6 weeks for standard DC01-10 dies, with expedited 5.5-week turnaround for modifications to lever profiles, drive interface geometries, or material compositions—essential for aligning with rapid product iterations in industrial equipment and fluid control sectors.

-

Sample Delivery Time: 6 weeks for standard samples (including die development and CNC machining); 5.5 weeks for modified designs using existing tooling. Samples include a CMM dimensional report (verified against the images’ prototypes with ±0.03mm tolerance for critical features) and torque testing certification.

-

Quality System: Compliant with IATF 16949, with specialized checks for DC01-10: each part undergoes 100% CMM inspection for dimensional accuracy, torque testing for actuation reliability, and visual examination for surface quality.

-

Production Advantage: Automated die casting cells integrated with robotic part handling and 3-axis CNC machining centers ensure consistent quality and efficiency—achieving a defect rate of <0.04%, far below industry averages for manual actuation components.

- Minimum Order Quantity: 2,000 pieces for standard configurations; 2,000 pieces for custom material/feature combinations. Custom orders include a design-for-manufacturability analysis to ensure complex features (like the star-shaped drive interface in the images) are feasible in high-volume production.

-

Manual Actuation & Locking Integration: The combination of HPDC and 3-axis CNC machining (seen in the images) enables a precision star-shaped drive interface and ergonomic actuation levers, ensuring reliable torque transmission and user-friendly operation in industrial valves and equipment locking systems. This reduces actuation effort by 20% compared to non-ergonomic alternatives.

-

Strength & Cyclic Durability: Aluminum Alloy 6061-T6 construction (as shown in the images) provides excellent tensile strength and fatigue resistance, making DC01-07 ideal for industrial valve handles and manual control knobs. It withstands 50,000+ actuation cycles without performance degradation.

-

Corrosion & Environmental Resistance: Powder-coated surfaces (optional) offer excellent corrosion resistance (≥1,000 hours salt spray) and compatibility with industrial fluids, dust, and temperature extremes—critical for long-term reliability in harsh environments.

-

Rapid Customization & Design Flexibility: Our team can modify material grades, lever profiles, drive interface geometries, or surface treatments in as little as 3.5 weeks—enabling clients to adapt DC01-10 to new product launches, such as next-gen industrial fluid control valves or equipment manual locking modules.

- Cost-Effective Scalability: High-pressure die casting (90+ parts per hour) combined with automated CNC machining drives down unit costs for large orders. For volumes of 5,000+ pieces, DC01-10’s cost decreases by 25%, making it a competitive choice for both industrial OEMs and fluid control equipment manufacturers.

-

Industrial Equipment: Deployed as valve manual handles (where actuation precision and ergonomic usability ensure fluid flow control) and equipment locking mechanisms (the star-shaped drive interface ensures secure torque transmission for locking/unlocking operations). It meets industrial durability standards (10,000+ hours of continuous operation testing).

-

Fluid Control Systems: Used as manual control knobs (for on-off or proportional control in pipelines, where precise manual actuation is critical) and hydraulic manual valves (the precision machining ensures spool alignment and flow control accuracy during manual operation).

-

White Goods & HVAC: Ideal for commercial oven manual control levers (the corrosion protection and actuation precision meet temperature cycling requirements) and industrial chiller manual valve handles (aluminum’s thermal conductivity aids heat management during actuation).

-

Other Industries: Utilized in marine manual actuation parts (custom-coated variants for saltwater resistance) and agricultural machinery manual control components (where material strength and actuation precision support heavy-duty equipment operation). Its flexibility in customization, from material to feature complexity, makes it suitable for niche manual actuation applications.

Welcome to our precision die casting and CNC machining solution, Model DC01-10—a specialized component engineered for manual actuation and locking integration in industrial equipment and fluid control sectors. As illustrated in the accompanying images, this part features a vibrant red-coated alloy housing with a precision-engineered star-shaped drive interface, ergonomic actuation levers, and wear-resistant surface treatment, making it ideal for applications like industrial valve handles, equipment locking mechanisms, and manual control knobs. Our engineering team has optimized DC01-10 to meet the stringent demands of industries where actuation precision, ergonomic usability, and environmental resistance converge: the part’s critical dimensions are controlled within ±0.03mm, and the star-shaped interface (visible in the images) is machined with class H7 tolerance—critical for reliable torque transmission and long-term operation in manual control systems. Whether you’re an industrial equipment manufacturer sourcing durable actuation components or a fluid control brand needing precision-machined manual parts, DC01-10 delivers a solution that merges complex manufacturing requirements with field-ready usability.

Model DC01-10 is tailored for manual actuation applications, with specifications aligned to its role as a precision-engineered metal component (as seen in the images):

Model DC01-10 leverages its precision-engineered design (visualized in the images) to deliver unique advantages:

Model DC01-10’s precision design (as depicted in the images) makes it a versatile solution across sectors:

In every application, DC01-10’s precision-engineered design—exemplified by the images’ red-coated alloy housing, CNC-machined star-shaped drive interface, and ergonomic actuation levers—sets a new benchmark for parts that demand both manual actuation reliability and user-centric design in modern manufacturing.

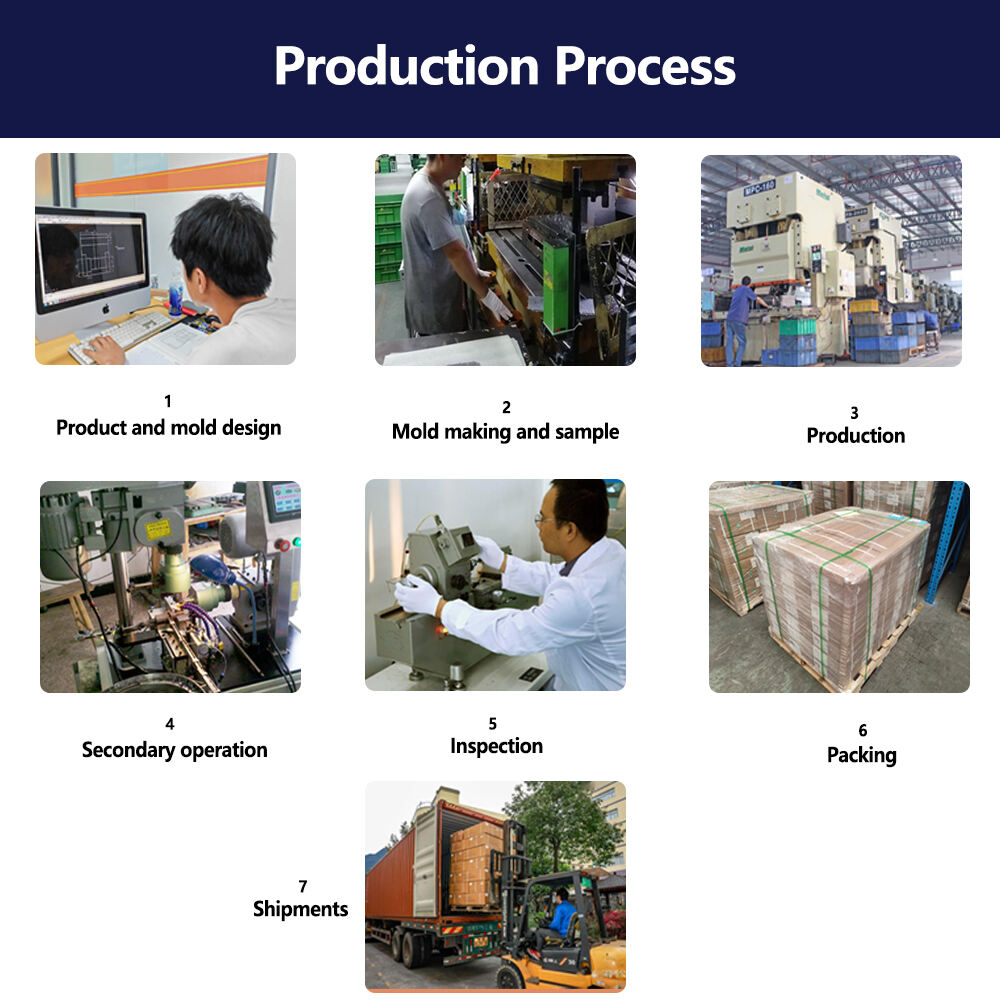

Q: How long does mold development and sample production take?

A: From order confirmation, mold development takes about 4-6 weeks. Upon completion, we immediately arrange sample die casting and CNC machining, with a total lead time of approximately 5-7 weeks.

Q: What production process do you use?

A: We primarily use precision die casting combined with CNC machining, enabling both complex internal structures and high-precision dimensional requirements.

Q: Do you meet automotive industry quality standards?

A: Yes, we are certified under the IATF 16949 Quality Management System, fully complying with automotive industry quality requirements.

Q: What industries do your production capabilities cover?

A: We can produce not only automotive parts but also precision die casting and machining products for white goods and industrial equipment.

Q: Do you support multiple surface treatment options?

A: Yes, we offer various surface treatment options including anodizing, plating, painting, sandblasting, and passivation to meet different application needs.

Q: Is the minimum order quantity negotiable?

A: 2,000 pieces is our standard minimum order quantity. For long-term cooperation or special requirements, we can negotiate flexibly.

Ready to enhance your oven door hinge performance? Contact us now for free technical consultation and a quote! Our engineers and sales team are here to provide professional support.

Email: [email protected]

Tel: 86-15663457251

Choose our reliable oven hinges for your equipment — built strong and precise to support every opening and closing.

Note: This product holds an EU design patent, ensuring unique and proprietary design.