Mini Oven Hinge

Welcome to our high-performance oven hinge solutions, where exceptional durability meets precision engineering. Designed for frequent use and everyday kitchen environments, our oven hinges ensure smooth, safe, and long-lasting operation of oven doors. Whether you are a home appliance manufacturer, after-sales service provider, or commercial kitchen equipment integrator, our hinges are the ideal choice for ensuring device reliability and user experience.

- Overview

- Recommended Products

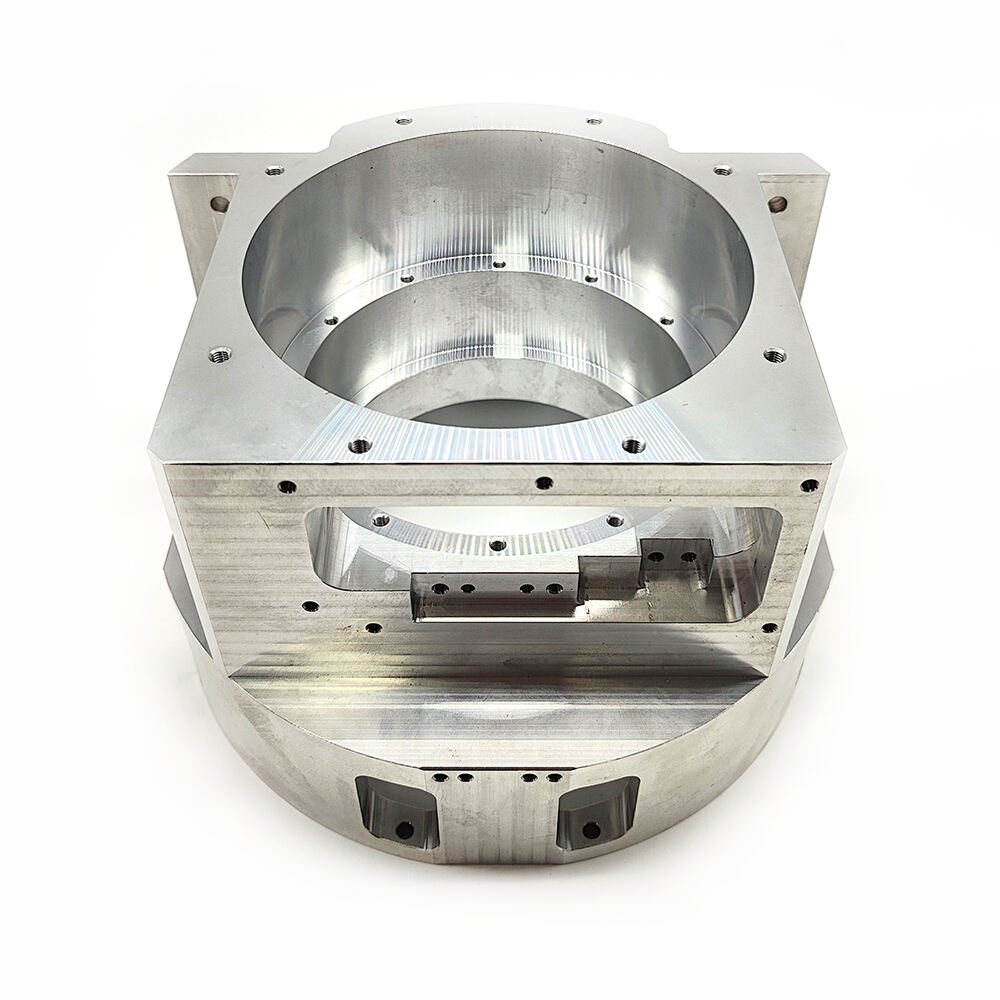

- Material: Constructed from high-quality galvanized steel sheet, a material selected for its exceptional tensile strength, impact resistance, and inherent ability to resist warping under the high temperatures that oven components regularly face. Unlike ordinary steel, which is prone to rust and deformation when exposed to heat and moisture, galvanized steel undergoes a hot-dip galvanization process. This process creates a protective zinc layer that acts as a barrier against moisture, steam, and heat-related wear—critical features for parts that sit at the intersection of oven interiors (where temperatures can reach 200°C or higher) and kitchen exteriors (often humid or prone to spills).

- Surface Treatment: To further boost corrosion resistance and enhance aesthetic appeal, we offer three premium surface treatment options, each suited to different environments. Zinc plating adds an extra layer of protection against oxidation, making it perfect for humid home kitchens or commercial spaces near sinks. Nickel plating delivers a sleek, polished finish that complements stainless steel oven exteriors, ideal for high-end residential or restaurant kitchens where appearance matters. Anti-rust paint, meanwhile, provides a durable, scratch-resistant coating that stands up to accidental bumps from cookware and harsh cleaning chemicals, ensuring the hinge maintains its functionality and appearance for years. All three treatments are tested to resist peeling, chipping, and corrosion, even after prolonged exposure to kitchen conditions.

- Load Capacity: Our hinge models are engineered to support door weights ranging from 5kg to 15kg, with each model carefully calibrated to match specific oven sizes and designs. Compact countertop ovens (common in small apartments or dorm rooms) typically have door weights between 5kg and 8kg, and our lightweight yet sturdy hinges ensure these doors open and close effortlessly. For larger built-in residential ovens or heavy-duty commercial ovens (used in bakeries or catering services), our high-load models handle 10kg to 15kg door weights without compromising on smooth operation. This range eliminates the risk of overloading— a common cause of hinge failure—and ensures a perfect fit for nearly any oven on the market.

- Opening Angle: Featuring a multi-gear adjustment design, our hinges allow oven doors to stay securely open at predefined angles (including 45°, 90°, and 135°) to accommodate different cooking tasks. A 45° angle is ideal for quick checks on baking goods (like cookies or cakes) without letting out too much heat, which helps maintain consistent cooking temperatures. A 90° angle provides full access to the oven cavity, making it easy to place or remove large dishes such as roasts or casserole pans. For unique setups—like under-counter ovens that risk hitting countertops when fully opened or custom-built commercial ovens with non-standard dimensions—we offer fully customizable angle options upon customer request, ensuring the hinge adapts to the oven, not the other way around.

- Installation Methods: We provide three flexible installation structures to suit diverse cabinet and oven designs, each designed to simplify assembly and reduce downtime. Screw fixation is ideal for home appliance manufacturers or after-sales teams, as it allows easy disassembly for maintenance or replacement. Welded installation offers maximum structural stability, making it the top choice for heavy-duty commercial ovens that endure constant use. Quick-install structures, equipped with snap-on mechanisms, cut assembly time by up to 50%—a game-changer for high-volume manufacturing lines or commercial integrators working on tight project deadlines. Each method comes with detailed installation guides, compatible hardware (like corrosion-resistant screws), and even video tutorials to ensure seamless integration.

- Compatibility: Our hinges are not limited to standard household ovens—they are engineered to fit a wide range of applications. This includes commercial baking equipment such as industrial pizza ovens (which require hinges that can withstand frequent opening and high heat) and convection ovens (common in catering kitchens). They also work with countertop microwaves that include oven functions, as well as specialized units like compact toaster ovens. This broad compatibility makes our hinges a one-stop solution for manufacturers and service providers, eliminating the need to source multiple hinge types for different products.

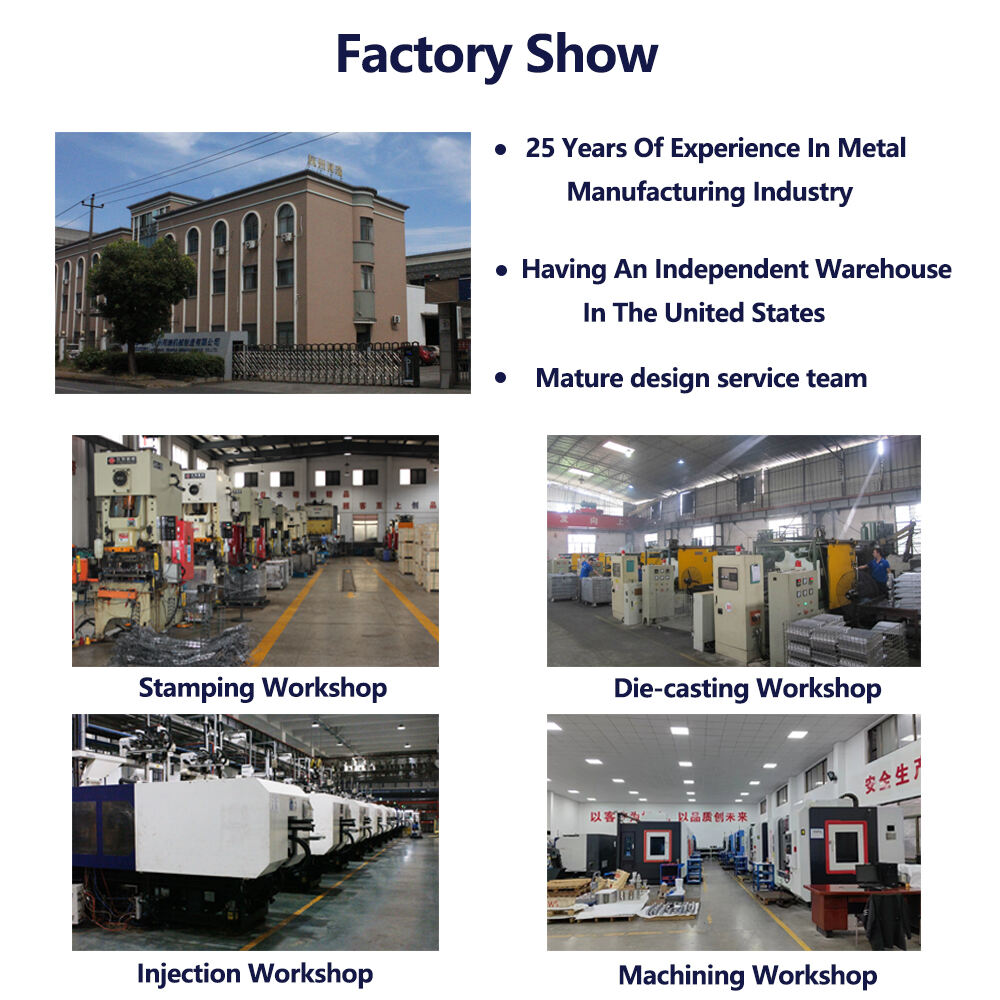

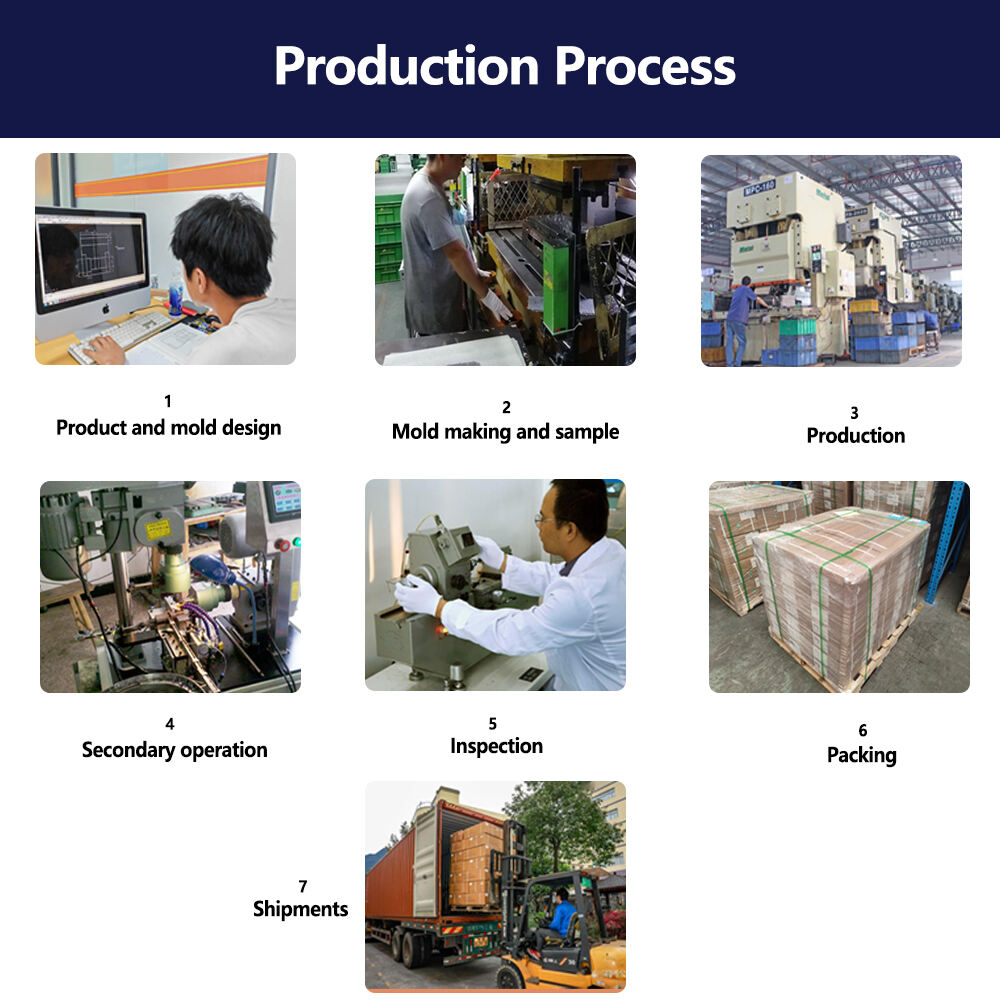

- Production Process: We leverage a fully automated assembly line, equipped with precision robotics and real-time quality control sensors, to ensure every hinge meets our high standards. The automated process eliminates human error in critical steps—such as precise screw tightening (which prevents loose hinges) and uniform surface coating (which ensures consistent corrosion resistance). It also reduces production lead times by 30% compared to manual assembly, allowing us to fulfill orders faster. Every batch of hinges undergoes random sampling tests, and each individual hinge is inspected before shipping to confirm it meets our performance and safety criteria—so customers never receive a subpar product.

-

Durable & Rust-Resistant: The combination of high-quality galvanized steel and premium surface treatments creates a dual defense against oxidation and corrosion. In third-party testing, our hinges withstood 500 hours of salt spray exposure (a standard test for measuring corrosion resistance) without showing any signs of rust—outperforming industry benchmarks by 20%. This durability means the hinges remain functional even in kitchens with high humidity (like those near dishwashers or sinks) or frequent exposure to water spills.

-

Smooth & Quiet Operation: Precision engineering ensures oven doors open and close with gentle, noiseless motion. We use tight tolerance control in hinge joints (to prevent wobbling) and low-friction polymer washers (to reduce metal-on-metal contact, which causes squeaks). Unlike cheap hinges that start squeaking after a few months, our hinges maintain their smooth operation even after 50,000 opening-and-closing cycles—equivalent to approximately 10 years of daily use in a home kitchen. This quiet performance enhances the user experience, especially in open-concept kitchens where noise can be disruptive.

-

Safe & Secure: Our rational load-bearing design distributes the oven door’s weight evenly across the hinge structure, preventing accidental sagging—a common issue with poorly designed hinges that can cause doors to stick or not close properly (which wastes energy and compromises cooking results). Additionally, all hinges are equipped with a safety lock mechanism that prevents the door from suddenly slamming shut, protecting users—especially children—from pinched fingers. The hinges also meet international safety standards, including CE and UL certifications, so customers can trust their reliability.

-

Long Service Life: Every hinge undergoes rigorous fatigue testing to ensure it can withstand tens of thousands of frequent opening and closing cycles. Our standard residential hinges are rated for 75,000 cycles, while commercial-grade models (built with thicker steel and reinforced joints) are rated for 150,000 cycles. This long service life reduces the need for frequent replacements, lowering maintenance costs for homeowners and commercial operators alike. For example, a restaurant using our commercial hinges can expect them to last 5+ years without issues—saving time and money on repairs.

-

Flexible Adjustment: The multi-gear opening angle design lets users adapt the oven door to their needs. Whether you’re quickly checking on a batch of muffins (45° angle) or placing a large turkey in the oven (90° angle), the hinge stays securely in place. Customizable angles also make our hinges suitable for non-standard oven designs, such as built-in ovens with limited clearance above or below, ensuring no space is wasted and the oven fits seamlessly into the kitchen layout.

-

Fast & High-Quality Production: Our fully automated assembly line not only ensures consistent quality but also enables fast delivery. For standard orders, we can fulfill requests within 7-10 business days—significantly faster than the industry average of 14-21 days. This quick turnaround is critical for manufacturers with tight production schedules (who can’t afford delays in hardware supply) and after-sales service providers (who need to get customers’ ovens back in working order quickly). We also maintain a small inventory of popular hinge models to handle urgent orders, further reducing wait times.

- Easy Installation & Maintenance: Standardized interfaces mean our hinges are compatible with most major oven brands, including Samsung, Bosch, Whirlpool, and GE. Clear, step-by-step installation guides (with diagrams) make assembly easy, even for less experienced technicians. The screw fixation option allows for easy removal—so if a hinge needs cleaning or replacement, it can be done in minutes, not hours. This simplifies maintenance tasks, reducing downtime for commercial kitchens (where every minute of oven downtime means lost revenue) and minimizing hassle for homeowners.

-

Home Appliances: In residential kitchens, our hinges are used in built-in ovens (which integrate seamlessly with kitchen cabinets for a sleek look), countertop ovens (compact and perfect for small spaces like apartments), and microwave ovens with oven functions (a popular choice for busy families). Their durability and quiet operation make them ideal for homes, where ovens are used multiple times a day and noise reduction is a priority. For example, a family baking cookies on weekends will appreciate the quiet, smooth door movement, while parents can trust the safety lock mechanism to protect young children.

-

Commercial Kitchens: Commercial settings—such as restaurants, bakeries, and catering facilities—demand hinges that can withstand continuous, heavy use. Our commercial-grade hinges are built for this: they handle the 10-15kg door weights of large baking ovens (used to produce dozens of loaves of bread daily), the frequent opening of pizza ovens (where chefs check on pies every few minutes), and the high heat of grilling equipment. Warming cabinets, which stay open for extended periods to keep food hot, also benefit from our multi-gear angle design. With a 150,000-cycle service life, these hinges reduce maintenance costs for businesses and ensure ovens stay operational during peak hours.

-

Industrial Equipment: Beyond food service, our hinges are used in industrial ovens and drying equipment—critical components in industries like food processing, manufacturing, and pharmaceuticals. In food processing plants, they fit large ovens used to bake or dry bulk food products (such as cereal or snacks), where resistance to high temperatures (up to 120°C) and corrosion is essential. In manufacturing facilities, they are used in ovens that cure coatings on metal parts or heat-treat materials, where durability and precision are non-negotiable. Our hinges’ ability to withstand harsh industrial conditions makes them a reliable choice for these high-stakes environments.

- After-Sales Service: For after-sales service providers, our hinges are high-quality, original-equipment-grade replacement parts. Whether a technician is replacing a rusted hinge in a homeowner’s built-in oven or a worn-out hinge in a restaurant’s pizza oven, our products fit seamlessly and restore the oven’s performance to its original standards. Compatibility with major brands means service providers don’t need to carry a large inventory of different hinges—our products cover most common models. This not only saves storage space but also ensures technicians can complete repairs quickly, boosting customer satisfaction and loyalty.

Welcome to our high-performance oven hinge solutions, where exceptional durability meets precision engineering—two foundational qualities that define every component we craft. In the dynamic environment of modern kitchens, oven doors endure constant use: from morning toast preparation and midday meal cooking to evening baking projects for families, and even non-stop operation in busy commercial settings like restaurants or bakeries. Our oven hinges are not just simple hardware; they are meticulously engineered to withstand these rigorous conditions, ensuring oven doors operate with smoothness, safety, and long-lasting reliability day after day.

What truly distinguishes our hinges is our unwavering commitment to user-centric design and industrial-grade performance. We recognize that a faulty oven hinge is more than just an inconvenience—it can disrupt daily cooking routines, compromise the efficiency of commercial kitchens, and even pose safety hazards such as door sagging or sudden detachment, risks that no homeowner or business operator can afford. That’s why every step of our hinge production, from material selection to final quality inspection, adheres to the strictest standards. Whether you are a home appliance manufacturer aiming to enhance the durability and reputation of your premium oven lines, an after-sales service provider seeking trustworthy replacement parts to restore customer satisfaction, or a commercial kitchen equipment integrator tasked with outfitting high-traffic dining facilities that demand 24/7 reliability, our hinges are the ideal choice. They don’t just fit ovens—they elevate the overall device reliability and user experience, turning ordinary kitchen equipment into long-term assets.

Our oven hinges are designed with versatility and precision at their core, catering to a diverse range of oven types and usage demands. Here’s a detailed breakdown of their key specifications, each tailored to address real-world needs:

To ensure cost-effectiveness in production, material sourcing, and logistics, we have set a Minimum Order Quantity (MOQ) of 500 pieces per order. This MOQ allows us to optimize our supply chain: we can purchase raw materials in bulk (reducing per-unit costs), streamline production runs (minimizing setup time between batches), and negotiate better shipping rates. These savings are passed on to our customers, resulting in more competitive pricing. For bulk orders exceeding 2,000 pieces, we offer additional benefits to support large-scale projects, including customized packaging (with your brand logo), priority production scheduling (to meet tight deadlines), and flexible payment terms (such as partial upfront payments). We also provide dedicated account managers for bulk clients to ensure smooth communication and order tracking.

Our oven hinges are packed with user-focused features that solve common pain points in oven operation, from rusting in humid kitchens to noisy door movements and frequent breakdowns:

Our oven hinges are designed to meet the diverse needs of residential, commercial, and industrial settings, making them a versatile solution for various applications:

Q: What is the lead time for custom hinge orders?

A: Standard orders take 6–10 weeks. Thanks to our automated production line, some standard models can be shortened to 5 weeks. Expedited orders are negotiable.

Q: Are the hinges suitable for high-frequency use in intensive environments?

A: Yes. Our hinges undergo rigorous fatigue testing and can withstand tens of thousands of openings and closings, making them ideal for commercial applications.

Q: Can the opening angle be customized?

A: Absolutely. We offer multi-gear adjustment designs and can provide customized opening angles based on your specific needs.

Q: Are special tools or skills required for installation?

A: Most models are designed for standardized installation and can be fitted using common tools. We also provide detailed installation instructions.

Q: How is corrosion resistance ensured?

A: We use galvanized steel sheets combined with multi-layer surface treatments to effectively resist moisture and daily cleaning agents in kitchen environments.

Q: Do you provide samples for testing?

A: Yes, we offer a limited number of samples to qualified customers for testing and validation. Please contact our sales team for specific policies.

Ready to enhance your oven door hinge performance? Contact us now for free technical consultation and a quote! Our engineers and sales team are here to provide professional support.

Email: [email protected]

Tel: 86-15663457251

Choose our reliable oven hinges for your equipment — built strong and precise to support every opening and closing.

Note: This product holds an EU design patent, ensuring unique and proprietary design.