MS01-01-Metal activity theory

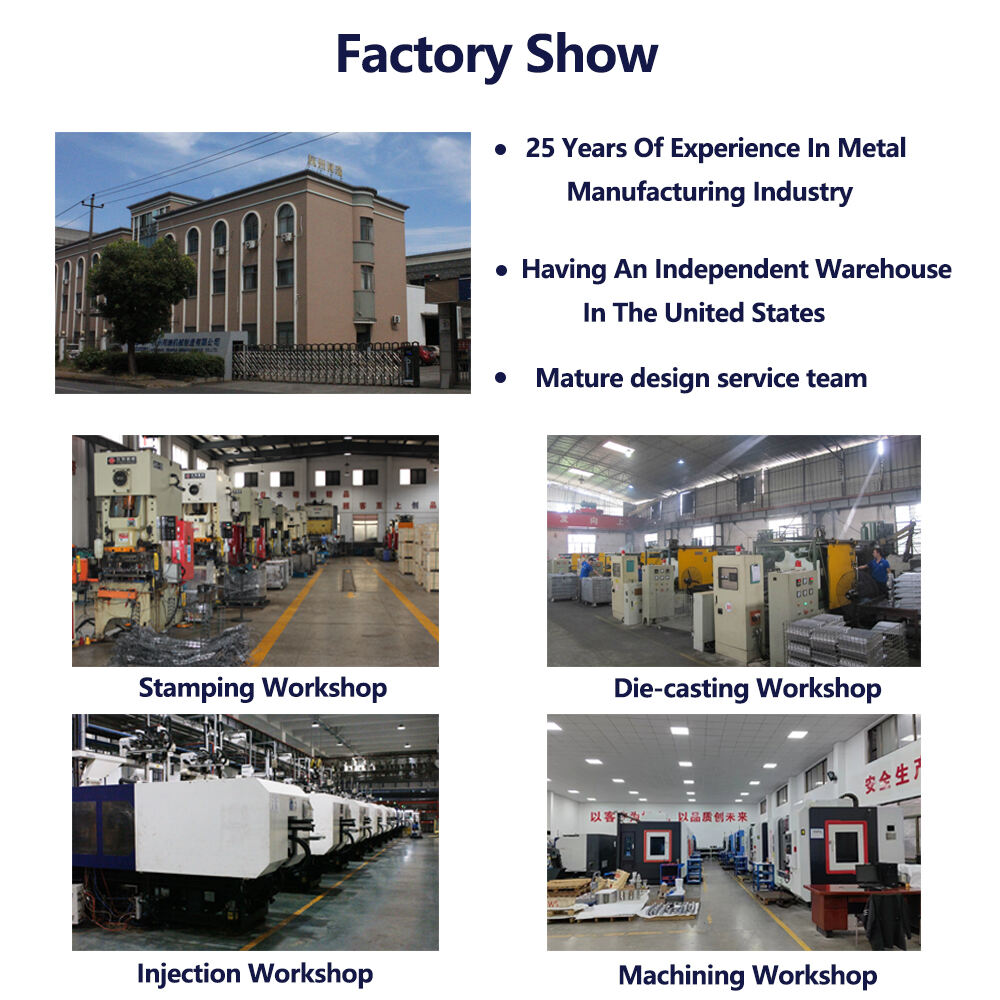

We specialize in the manufacturing of precision metal parts, with a professional design and production team dedicated to providing customers with high-quality, highly consistent metal component solutions. Leveraging advanced progressive stamping die technology, metal drawing processes, and fully automated production lines, we offer one-stop services from design support to mass delivery. Our products are widely used in white goods, automotive parts, and other industrial sectors.

- Overview

- Recommended Products

-

Materials: Exclusively uses high-quality galvanized steel (SGCC grade, 0.8-2.0mm thickness), 304/316 stainless steel (for corrosion-prone applications), and 6061 aluminum alloy—selected based on MS01-01’s target use cases. Galvanized steel is the default for white goods (e.g., refrigerator door hinges) due to its cost-effectiveness and rust resistance; 304 stainless steel is recommended for automotive underbody components (withstanding road salt exposure); and 6061 aluminum alloy suits lightweight needs, such as air conditioner fan brackets. Each material undergoes pre-production testing to ensure it meets MS01-01’s tensile strength requirements (minimum 300 MPa for galvanized steel, 505 MPa for 304 stainless steel).

-

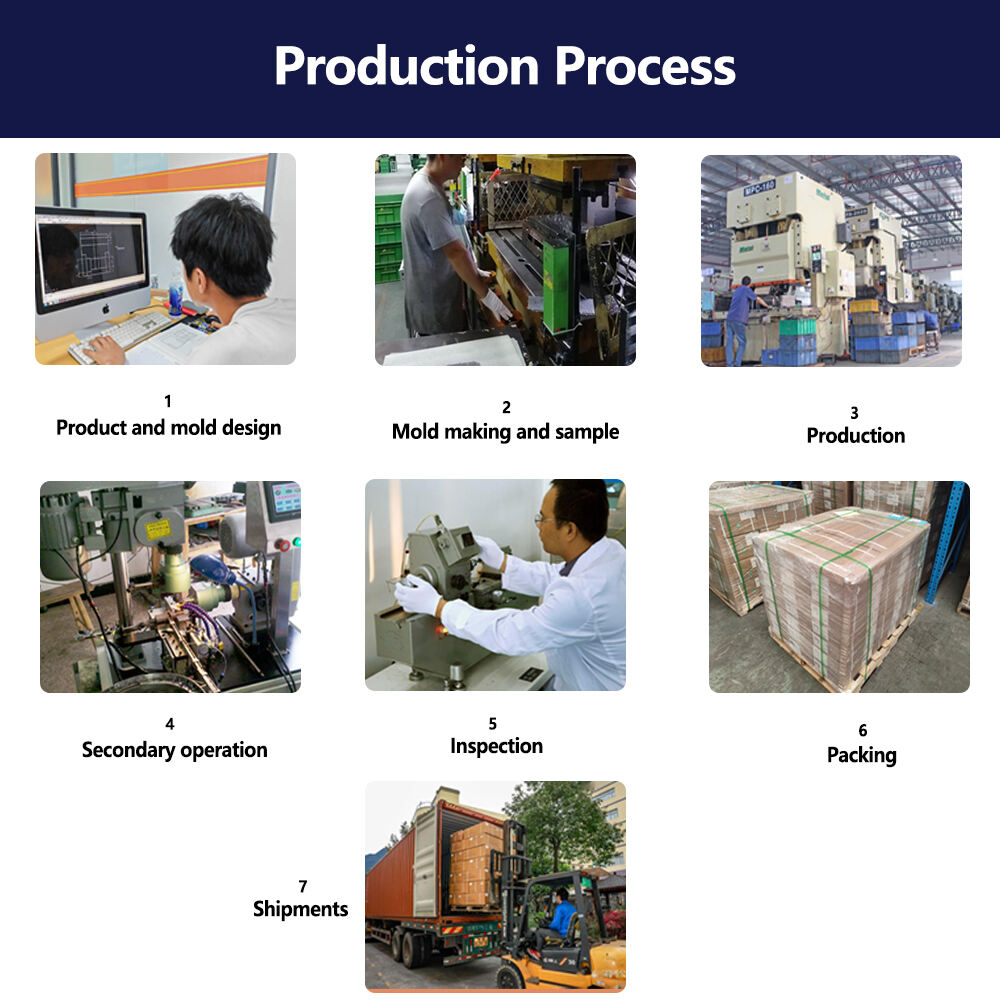

Production Process: MS01-01 relies on custom-engineered progressive stamping dies (with 8-12 stations) and metal drawing processes, optimized for the model’s typical part geometries—such as flat brackets, curved connectors, and shallow-drawn enclosures. The progressive stamping process for MS01-01 achieves a production rate of 120 parts per minute, while metal drawing ensures uniform wall thickness (±0.05mm) for components like washing machine water pump housings. Both processes are integrated into fully automated lines, with in-line sensors specific to MS01-01’s dimensions to reject out-of-tolerance units in real time.

-

Surface Treatment: Offers model-specific surface treatment options aligned with MS01-01’s application. For white goods use, galvanization (50-80μm zinc coating) or electrophoretic coating (black or gray, 15-25μm) provides enhanced rust resistance; for automotive parts, nickel plating (10-15μm) delivers a corrosion-resistant finish that matches automotive aesthetics; for commercial equipment, passivation (for stainless steel variants) or painting (polyester powder coating, 60-80μm) ensures durability against cleaning chemicals. All treatments for MS01-01 undergo 48-hour salt spray testing to confirm corrosion resistance.

-

Mold Development Cycle: 6 weeks exclusively for MS01-01’s custom molds—accelerated by our dedicated mold team that uses 3D printing for rapid prototyping of die components. This cycle includes design validation (to ensure molds match MS01-01’s exact dimensions), material selection for dies (H13 tool steel, heat-treated to 52-54 HRC for longevity), and trial runs to fine-tune stamping/drawing parameters for the model.

-

Sample Delivery Time: 45 days for MS01-01 samples, a timeline that includes mold fabrication (6 weeks), sample production (3 days), quality inspection (2 days), and shipping. Unlike generic samples, MS01-01 samples include a detailed test report with dimensional measurements (via CMM), material certification, and surface treatment performance data—helping customers validate compatibility with their assembly lines early.

-

Quality System: MS01-01 is fully compliant with the IATF 16949 Quality Management System, with model-specific quality checkpoints. For example, every 100th MS01-01 part undergoes dimensional inspection using a coordinate measuring machine (CMM) to ensure ±0.02mm tolerance; surface treatments are tested for adhesion (cross-cut test) and corrosion resistance (salt spray); and tensile strength is verified via sample testing every production batch.

- Production Advantage: MS01-01 is manufactured on dedicated fully automated stamping and drawing lines, equipped with intelligent vision inspection systems that capture 200+ data points per part to detect defects (e.g., burrs, dimensional in real time. This automation reduces human error to less than 0.01% for MS01-01, ensuring high precision and consistent output—critical for customers requiring large batches of interchangeable parts.

- Minimum Order Quantity: 1,000 pieces and above for standard MS01-01 configurations; customization (e.g., material switches, surface treatment changes, or minor dimension adjustments) is supported with a minimum order of 2,000 pieces. Customized MS01-01 orders include a pre-production design review to confirm modifications align with the model’s structural integrity and production feasibility.

-

Model-Specific Professional Support: Our experienced design and engineering team provides dedicated support for MS01-01, from initial drawing reviews (to ensure compatibility with customer assembly) to post-delivery troubleshooting. For example, if a white goods customer needs MS01-01 to fit a new oven door design, our team can adjust the part’s mounting hole positions while maintaining its structural strength—all within the model’s production capabilities.

-

Optimized Production for MS01-01: The progressive stamping and metal drawing processes are fine-tuned for MS01-01’s typical geometries, ensuring precise dimensions (±0.02mm tolerance) and strong consistency across batches. Unlike generic parts that may vary due to one-size-fits-all processes, MS01-01’s production parameters (e.g., stamping pressure, drawing speed) are fixed for the model, eliminating batch-to-batch differences—a critical advantage for automotive customers requiring parts that meet strict interchangeability standards.

-

Targeted Strength & Durability: MS01-01’s material selection and structural optimization are tailored to its application fields. For white goods, galvanized steel variants are optimized for impact resistance (withstanding 50N impact without deformation, ideal for refrigerator door components); for automotive parts, stainless steel variants undergo heat treatment to enhance fatigue resistance (enduring 100,000+ vibration cycles, suitable for engine bay components); for industrial equipment, aluminum alloy variants are lightweight yet strong (30% lighter than steel, reducing overall device weight).

-

Rapid Turnaround for MS01-01: Our dedicated mold team ensures 6-week mold development for MS01-01, and 45-day sample delivery—30% faster than industry averages for custom metal parts. This rapid response is possible because we maintain a library of MS01-01’s standard mold components, reducing design and fabrication time. For urgent orders, we offer expedited mold development (4 weeks) and sample delivery (30 days) for an additional fee.

-

MS01-01 Cost Advantage: Economies of scale from MS01-01’s dedicated production lines, combined with process optimization (e.g., reducing material waste to less than 5%), enable highly competitive pricing. For example, bulk orders of 10,000+ MS01-01 parts benefit from a 15% cost reduction compared to small-batch orders, making it an affordable choice for both large manufacturers and mid-sized suppliers.

-

Comprehensive Quality Control for MS01-01: Full-process quality monitoring based on IATF 16949 standards, with model-specific checkpoints. Every MS01-01 part undergoes three inspections: pre-production (material certification), in-production (real-time vision inspection), and post-production (dimensional and performance testing). This ensures that less than 0.05% of MS01-01 parts are defective—well below the industry average of 0.2%.

- Flexible Customization for MS01-01: While MS01-01 has standard configurations, we support comprehensive customization to meet specific needs. This includes material switches (e.g., from galvanized steel to 304 stainless steel for corrosion-prone applications), surface treatment changes (e.g., from painting to nickel plating for aesthetic requirements), and minor dimension adjustments (e.g., modifying part length by ±5mm). All customizations are validated via sample testing to ensure they don’t compromise MS01-01’s performance.

-

White Goods: MS01-01 serves as a critical component in household appliances, including refrigerator door hinges (galvanized steel variant, corrosion-resistant for kitchen humidity), washing machine motor brackets (stainless steel variant, vibration-resistant), air conditioner fan housings (aluminum alloy variant, lightweight), and oven door latches (galvanized steel with electrophoretic coating, heat-resistant up to 150°C). Its precise dimensions ensure seamless assembly with appliance OEM lines, reducing production downtime.

-

Automotive Parts: In the automotive industry, MS01-01 is used for structural components (e.g., chassis brackets, 304 stainless steel variant with high tensile strength), functional parts (e.g., fuel line connectors, corrosion-resistant nickel-plated finish), and electrical connectors (aluminum alloy variant with conductive coating). It meets automotive-grade durability standards, withstanding extreme temperatures (-40°C to 120°C) and road salt exposure—making it suitable for both interior and exterior automotive applications.

-

Commercial Equipment: MS01-01 provides structural support and enclosure solutions for commercial refrigeration equipment (e.g., display case frames, stainless steel variant with passivation for food safety), commercial kitchenware (e.g., oven shelves, heat-resistant painted finish), and vending machines (e.g., coin slot brackets, durable galvanized steel). Its consistency ensures that commercial equipment manufacturers can scale production without worrying about part variability.

-

Industrial Sector: For industrial use, MS01-01 is integrated into instrumentation (e.g., sensor mounting brackets, aluminum alloy for lightweight precision), electronic devices (e.g., circuit board enclosures, stainless steel for EMI shielding), and mechanical structural components (e.g., conveyor belt brackets, high-strength galvanized steel). Its compliance with IATF 16949 standards makes it a reliable choice for industries with strict quality requirements, such as aerospace and medical equipment (as non-critical components).

- Other Industries: MS01-01 also finds applications in office equipment (e.g., printer paper tray slides, smooth nickel-plated finish for easy movement), communication chassis (e.g., router enclosure parts, aluminum alloy for heat dissipation), and lighting fixtures (e.g., LED bracket arms, lightweight and corrosion-resistant). Its flexibility in customization allows it to adapt to the unique needs of these diverse sectors, making it a versatile precision metal part solution.

Welcome to our specialized precision metal parts solution, with Model MS01-01 standing as a benchmark of high-quality, consistent performance tailored for industrial-grade applications. Unlike generic metal components that prioritize basic functionality, MS01-01 is engineered to meet the strict dimensional accuracy and durability demands of white goods, automotive, and commercial equipment sectors—leveraging our core strengths in advanced manufacturing. Our dedicated design and production team works exclusively with Model MS01-01 to refine every detail: from material selection (curated to match the model’s intended use cases) to process optimization, ensuring it delivers reliable performance in high-stress environments, such as the vibration-prone interior of washing machines or the temperature-fluctuating housing of automotive components.

At the heart of MS01-01’s excellence is our integration of progressive stamping die technology, metal drawing processes, and fully automated production lines—all calibrated specifically for this model to eliminate variability. For example, the progressive stamping dies used for MS01-01 are precision-machined to achieve a dimensional tolerance of ±0.02mm, a critical requirement for its role in fitting seamlessly with assembly lines of white goods and automotive parts. We don’t just offer a part; we provide a one-stop service for MS01-01, from design tweaks (to align with customer-specific assembly needs) to mass delivery, with every unit adhering to the same rigorous standards. Whether you’re a white goods manufacturer needing consistent metal brackets for oven door mechanisms, an automotive supplier sourcing reliable structural components, or an industrial equipment integrator seeking parts that reduce assembly time, Model MS01-01 is the ideal choice—it transforms generic metal part expectations into a specialized, application-ready solution.

Model MS01-01 is designed to balance versatility, precision, and industry-specific performance, with each parameter optimized to enhance its compatibility and reliability. Here’s a detailed breakdown of its key specifications, tailored to highlight the model’s unique advantages:

Model MS01-01 combines the core benefits of our precision metal parts with model-specific enhancements, addressing industry pain points such as inconsistency, slow lead times, and poor compatibility:

Model MS01-01 is engineered to excel in diverse industrial sectors, with its design and performance tailored to address the unique needs of each field:

Q: How long does mold development and sample production take?

A: Mold development takes 6 weeks, and sample delivery is completed within 45 days, ensuring a quick response to customer needs.

Q: What production process do you use?

A: We use progressive stamping dies combined with metal drawing processes for production, ensuring high efficiency, precision, and excellent consistency, particularly suitable for parts with complex geometries.

Q: Do you meet automotive industry quality standards?

A: Yes, we are certified under the IATF 16949 Quality Management System, fully complying with automotive industry quality requirements.

Q: What are the advantages of metal drawing process?

A: The metal drawing process can produce deep thin-walled parts while maintaining uniform wall thickness and excellent surface quality, making it particularly suitable for manufacturing housings and container-type parts.

Q: What industries do your production capabilities cover?

A: We can produce not only metal parts for household appliances but also precision metal parts for automotive components, including both stamped and drawn parts.

Q: Do you support multiple surface treatment options?

A: Yes, we offer various surface treatment options including galvanization, nickel plating, painting, electrophoretic coating, and passivation to meet different application needs.

Q: Is the minimum order quantity negotiable?

A: 1,000 pieces is our standard minimum order quantity. For long-term cooperation or special requirements, we can negotiate flexibly.

Ready to enhance your oven door hinge performance? Contact us now for free technical consultation and a quote! Our engineers and sales team are here to provide professional support.

Email: [email protected]

Tel: 86-15663457251

Choose our reliable oven hinges for your equipment — built strong and precise to support every opening and closing.

Note: This product holds an EU design patent, ensuring unique and proprietary design.