MS01-06-Metal stamping refrigerator components

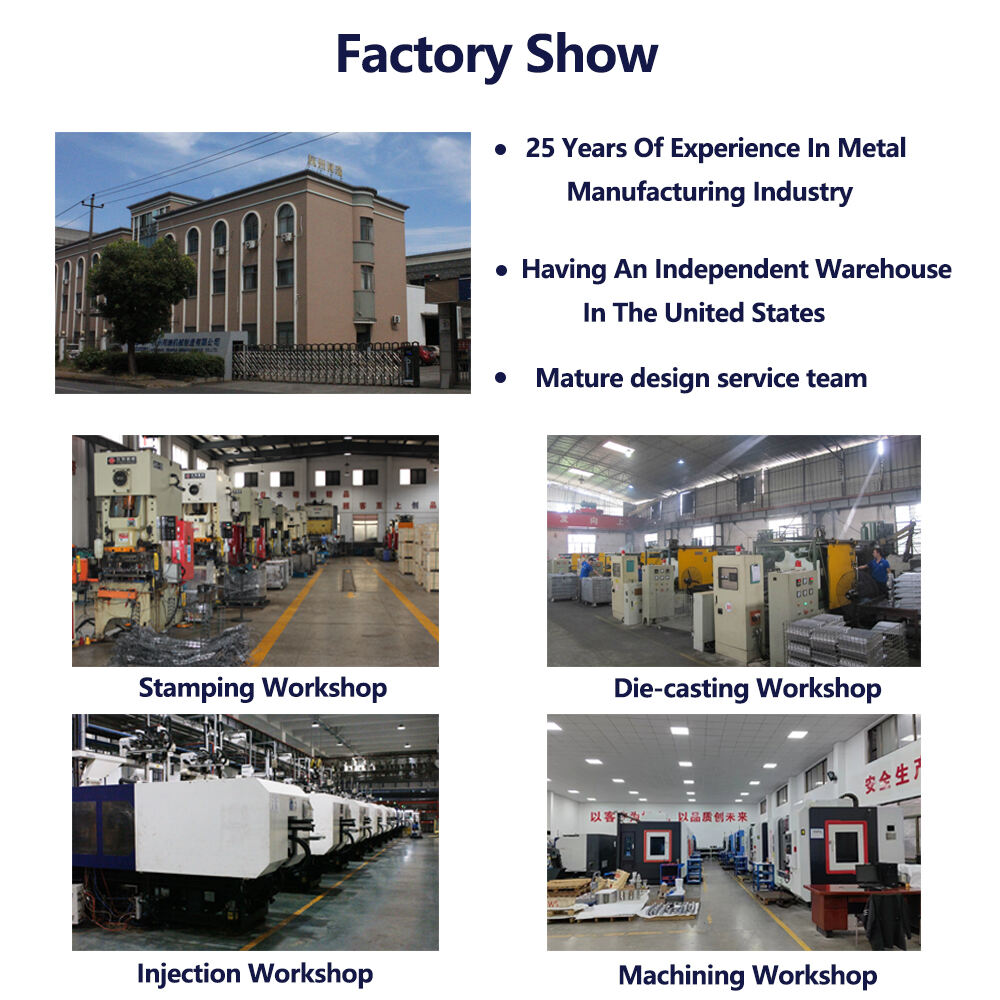

We specialize in the manufacturing of precision metal parts, with a professional design and production team dedicated to providing customers with high-quality, highly consistent metal component solutions. Leveraging advanced progressive stamping die technology, metal drawing processes, and fully automated production lines, we offer one-stop services from design support to mass delivery. Our products are widely used in white goods, automotive parts, and other industrial sectors.

- Overview

- Recommended Products

-

Materials: Primarily utilizes 304 stainless steel (0.3–0.8mm thickness) for its excellent corrosion resistance and formability, ideal for the part’s intricate cutouts and flat profile. Optional materials include galvanized steel (for cost-sensitive white goods applications) or 5052 aluminum alloy (for lightweight automotive interior components). All materials undergo flatness testing (≤0.1mm deviation) and tensile strength verification (≥515 MPa for 304 stainless steel).

-

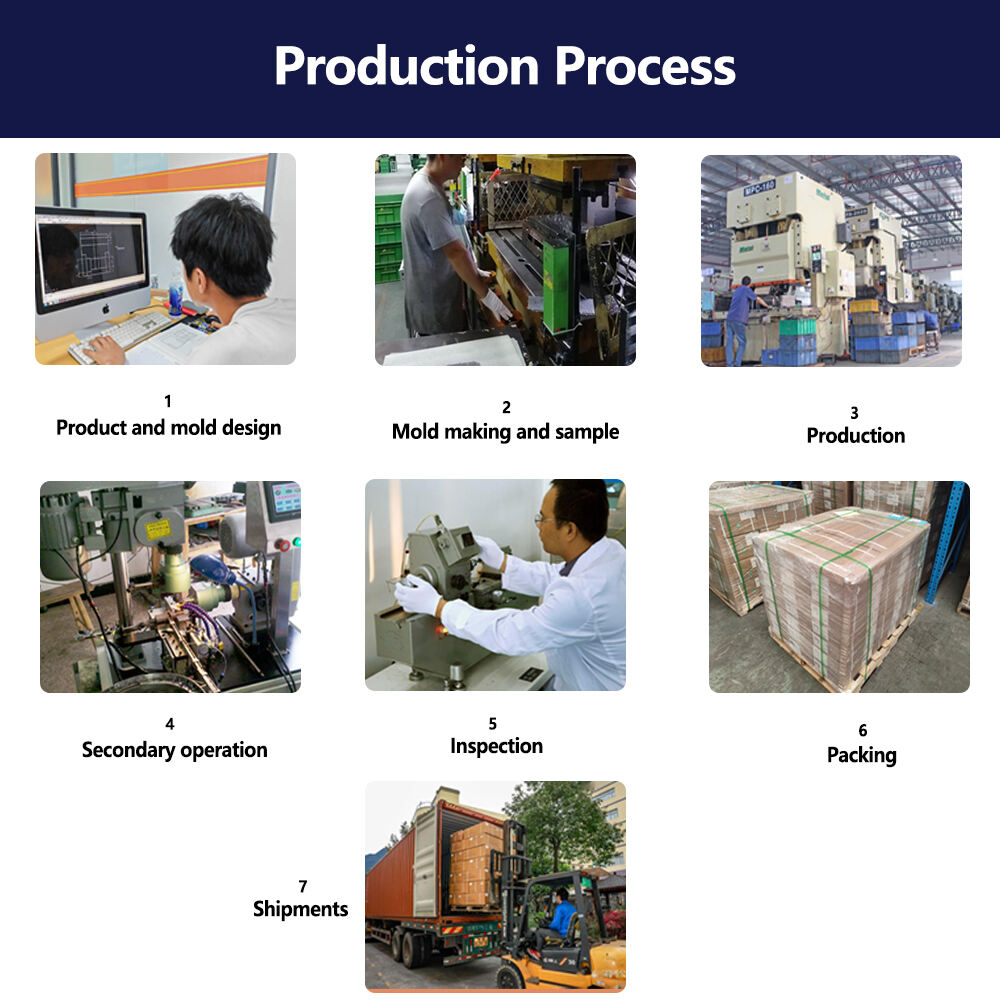

Production Process: Relies on high-speed progressive stamping dies (12–16 stations) to achieve the part’s complex geometry—including the precise notches and mounting hole visible in the image. The stamping process operates at 200+ strokes per minute, with in-line laser inspection to ensure dimensional accuracy. Unlike traditional stamping, MS01-06’s production incorporates stress-relief annealing post-stamping to maintain flatness, a critical step for thin-gauge parts prone to warping.

-

Surface Treatment: Supports passivation (for 304 stainless steel variants) to enhance corrosion resistance, electrophoretic coating (for color-matched white goods components), or electropolishing (for medical-grade applications requiring ultra-smooth surfaces). The image shows the natural finish of 304 stainless steel, but all surface treatments undergo 96-hour salt spray testing to ensure durability.

-

Mold Development Cycle: 6 weeks for standard MS01-06 molds, with expedited 3-week turnaround for modifications to cutout shapes or hole positions—essential for aligning with evolving product designs.

-

Sample Delivery Time: 45 days for standard samples; 30 days for modified designs using existing tooling. Samples include a flatness report (measured via optical profilometry) and dimensional conformance data (verified against the image’s prototype with ±0.015mm tolerance).

-

Quality System: Compliant with IATF 16949, with specialized checks for MS01-06: each part undergoes 100% visual inspection for burrs (≤0.02mm height) and flatness testing (≤0.1mm deviation).

-

Production Advantage: Automated stamping lines with AI-powered vision systems inspect every part for dimensional errors, surface defects, and flatness issues—ensuring the part in the image is representative of all units produced. This automation achieves a defect rate of <0.05%, far below industry averages.

- Minimum Order Quantity: 1,000 pieces for standard configurations; 1,500 pieces for custom material/finish combinations. Custom orders include a design-for-manufacturability review to ensure complex geometries (like the part’s notches) are feasible in high-volume stamping.

-

Ultra-Precise Geometry: The progressive stamping process creates the part’s intricate notches and mounting hole (seen in the image) with ±0.015mm tolerance—critical for parts that interface with sensors, electronics, or automated machinery. This precision eliminates the need for secondary machining, reducing production costs by 25%.

-

Exceptional Flatness: Post-stamping stress-relief annealing ensures the part maintains a flatness of ≤0.1mm over its entire surface—vital for applications like EMI shielding (where gaps compromise performance) or gasket sealing (where warping causes leaks).

-

Material Versatility: While the image shows 304 stainless steel, MS01-06 can be produced in galvanized steel (for cost efficiency) or aluminum (for weight reduction), with each material retaining the part’s precise geometry. This flexibility allows clients to balance performance and cost across different product lines.

-

Rapid Design Iteration: Our mold team can modify cutout shapes, hole positions, or material thicknesses in as little as 3 weeks—enabling clients to quickly adapt MS01-06 to new product iterations, such as updated appliance control panels or automotive sensor housings.

- Cost-Effective Scalability: High-speed stamping (200+ strokes per minute) and automated inspection drive down unit costs for large orders. For volumes of 10,000+ pieces, MS01-06’s cost decreases by 20%, making it viable for both high-end electronics and mass-market white goods.

-

Electronics: Serves as EMI shielding plates (where the part’s flatness and precision cutouts block electromagnetic interference) and circuit board retainers (securing components while maintaining thermal conductivity). The 304 stainless steel variant meets electronics industry standards for corrosion resistance and conductivity.

-

White Goods: Used as gaskets in oven control panels (where the part’s flatness ensures a tight seal against moisture) and mounting plates for refrigerator sensors (the precise hole aligns with wiring harnesses). Galvanized steel variants offer cost efficiency for high-volume appliance production.

-

Automotive Parts: Deployed as interior trim brackets (where the thin gauge reduces weight without sacrificing strength) and sensor mounting plates (the precise cutouts position components within ±0.02mm of design specs). Aluminum variants are ideal for electric vehicles, contributing to weight reduction goals.

-

Industrial Sector: Applied in instrumentation faceplates (where the part’s aesthetics and precision meet industrial design standards) and valve gaskets (the flatness ensures leak-free operation). The part’s corrosion resistance makes it suitable for harsh environments like chemical processing plants.

-

Other Industries: Utilized in medical device components (electropolished variants meet biocompatibility standards) and communication equipment shields (blocking interference in routers and base stations). Custom surface finishes, like the natural stainless steel in the image or colored electrophoretic coatings, align with brand identities.

Welcome to our precision metal part solution, Model MS01-06—an exemplar of thin-gauge, high-precision metal stamping engineered for applications demanding flatness, dimensional accuracy, and corrosion resistance. As illustrated in the accompanying image, MS01-06 features a complex, contoured shape with precise cutouts and a single mounting hole, making it ideal for use as a shielding plate, functional gasket, or structural insert in electronics, white goods, and automotive systems. Our engineering team has optimized MS01-06 to meet the stringent requirements of industries where even minor deviations can impact performance: the part’s flatness is controlled within 0.1mm over its entire surface, and the cutout geometries (visible in the image) are produced with ±0.015mm tolerance—critical for seamless integration into automated assembly lines. Whether you’re a electronics manufacturer needing EMI shielding plates or a white goods brand sourcing precision gaskets, MS01-06 delivers a solution that marries form and function in thin-gauge metal fabrication.

Model MS01-06 is tailored for thin-gauge precision, with specifications aligned to its role as a flat, feature-rich metal component (as seen in the image):

Model MS01-06 leverages its thin-gauge, precision-stamped design (visualized in the image) to deliver unique advantages:

Model MS01-06’s thin-gauge, precision design (as depicted in the image) makes it a versatile solution across sectors:

In every application, MS01-06’s precision-stamped, thin-gauge design—exemplified by the image’s complex geometry and flawless flatness—sets a new benchmark for parts that demand both accuracy and adaptability in modern manufacturing.

Q: How long does mold development and sample production take?

A: Mold development takes 6 weeks, and sample delivery is completed within 45 days, ensuring a quick response to customer needs.

Q: What production process do you use?

A: We use progressive stamping dies combined with metal drawing processes for production, ensuring high efficiency, precision, and excellent consistency, particularly suitable for parts with complex geometries.

Q: Do you meet automotive industry quality standards?

A: Yes, we are certified under the IATF 16949 Quality Management System, fully complying with automotive industry quality requirements.

Q: What are the advantages of metal drawing process?

A: The metal drawing process can produce deep thin-walled parts while maintaining uniform wall thickness and excellent surface quality, making it particularly suitable for manufacturing housings and container-type parts.

Q: What industries do your production capabilities cover?

A: We can produce not only metal parts for household appliances but also precision metal parts for automotive components, including both stamped and drawn parts.

Q: Do you support multiple surface treatment options?

A: Yes, we offer various surface treatment options including galvanization, nickel plating, painting, electrophoretic coating, and passivation to meet different application needs.

Q: Is the minimum order quantity negotiable?

A: 1,000 pieces is our standard minimum order quantity. For long-term cooperation or special requirements, we can negotiate flexibly.

Ready to enhance your oven door hinge performance? Contact us now for free technical consultation and a quote! Our engineers and sales team are here to provide professional support.

Email: [email protected]

Tel: 86-15663457251

Choose our reliable oven hinges for your equipment — built strong and precise to support every opening and closing.

Note: This product holds an EU design patent, ensuring unique and proprietary design.