MS01-03-Metal stamping and electroplating parts

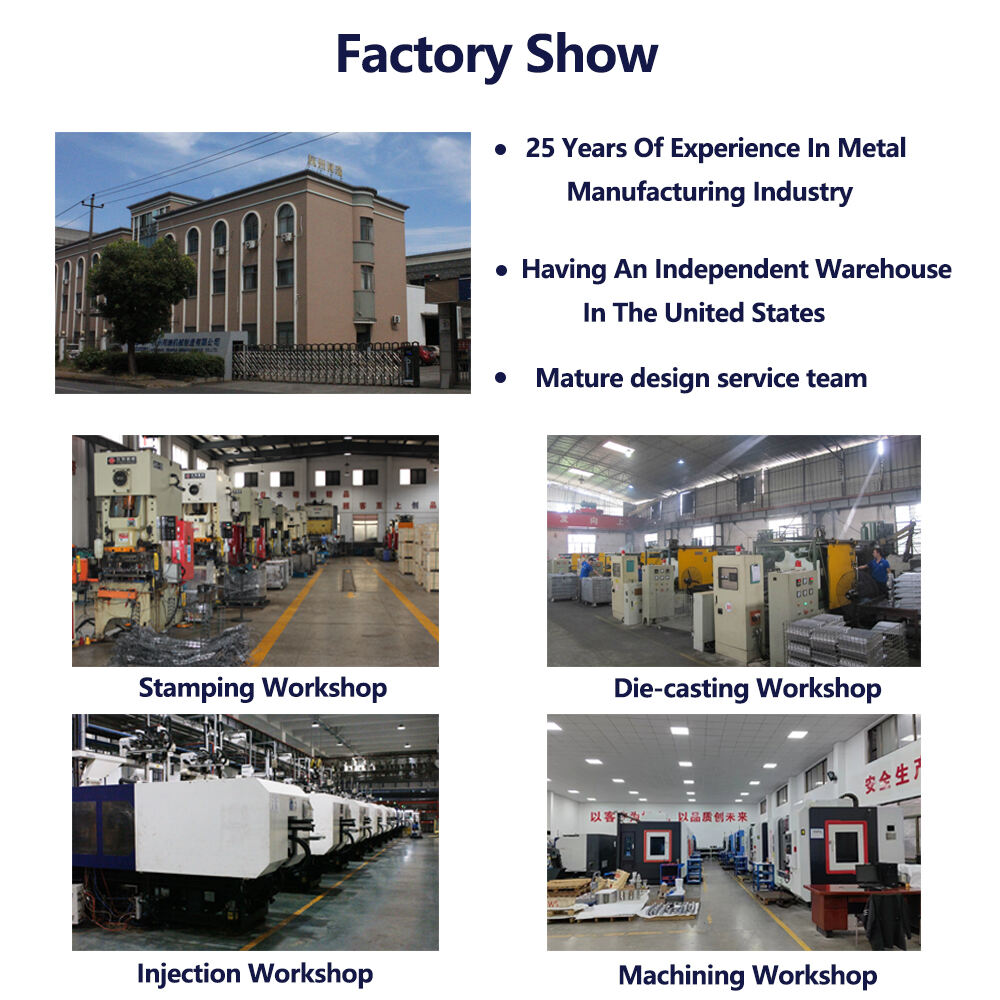

We specialize in the manufacturing of precision metal parts, with a professional design and production team dedicated to providing customers with high-quality, highly consistent metal component solutions. Leveraging advanced progressive stamping die technology, metal drawing processes, and fully automated production lines, we offer one-stop services from design support to mass delivery. Our products are widely used in white goods, automotive parts, and other industrial sectors.

- Overview

- Recommended Products

-

Materials: Offers an expanded material range to suit MS01-03’s broad compatibility: high-strength galvanized steel (SGCH grade, 0.5-3.0mm thickness, for load-bearing parts like commercial refrigeration brackets), 316L stainless steel (for chemical-resistant applications such as medical equipment enclosures), 5052 aluminum alloy (lighter than 6061, ideal for communication chassis), and carbon steel (SPCC grade, cost-effective for non-corrosive industrial structural parts). Each material undergoes pre-production bend testing (minimum 180° bend without cracking) and tensile strength verification (320 MPa+ for galvanized steel, 515 MPa+ for 316L stainless steel) to ensure alignment with MS01-03’s performance standards.

-

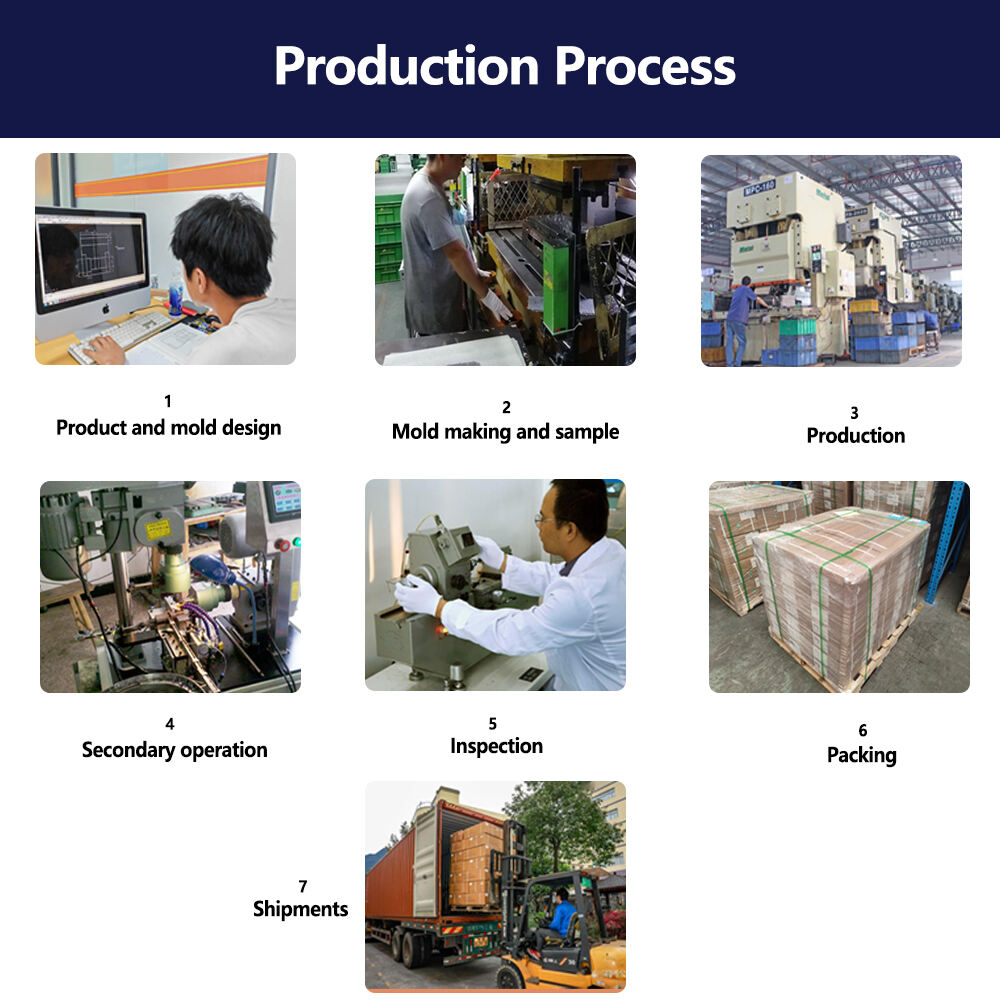

Production Process: MS01-03 utilizes adaptive progressive stamping dies (14-18 stations) and variable-depth metal drawing processes. The stamping system adjusts pressure and feed rate automatically based on material thickness—e.g., 0.5mm aluminum requires 25% less stamping force than 3.0mm galvanized steel—ensuring consistent precision across variants. Metal drawing for MS01-03 accommodates depths from 5mm to 30mm (vs. standard 5-15mm), enabling production of deep-drawn parts like washing machine water inlet housings. Both processes run on modular automated lines with quick-change tooling, reducing switchover time between part types to under 2 hours.

-

Surface Treatment: Provides application-specific options tailored to MS01-03’s diverse use cases. For electronic enclosures (a key MS01-03 application), conductive zinc-nickel plating (8-12μm) ensures EMI shielding; for outdoor commercial equipment, powder coating with UV resistance (70-90μm) prevents fading and corrosion; for food-grade commercial kitchenware, electropolished stainless steel (Ra ≤ 0.8μm) meets FDA standards; and for automotive interior parts, matte black electrophoretic coating (12-20μm) matches interior aesthetics. All treatments for MS01-03 pass 72-hour salt spray testing (extended from standard 48 hours) for enhanced durability.

-

Mold Development Cycle: 6 weeks for standard MS01-03 molds, with a “rapid-adapt” option for existing molds: modifying station configurations or adjusting cavity dimensions takes 1-2 weeks (vs. 4-6 weeks for new molds). This is enabled by the model’s modular die design—critical for clients needing quick tweaks to existing parts, such as resizing mounting holes for updated white goods models.

-

Sample Delivery Time: 45 days for standard MS01-03 samples; for modified designs using existing mold adaptations, delivery is shortened to 30 days. MS01-03 samples include a “compatibility report” that lists dimensional tolerances (±0.03mm for standard parts, ±0.05mm for deep-drawn variants), material compatibility with common assembly adhesives/fasteners, and environmental performance data (temperature resistance: -50°C to 180°C).

-

Quality System: Fully compliant with IATF 16949, with MS01-03-specific quality gates. For deep-drawn parts, every 50th unit undergoes wall thickness uniformity testing (±0.08mm tolerance); for conductive-coated variants, electrical resistance is measured (≤ 5Ω/sq); and for load-bearing parts, 100% of samples undergo 24-hour load testing (sustaining 1.5x rated weight without deformation).

-

Production Advantage: Manufactured on modular automated lines with AI-powered vision inspection that identifies 30+ defect types (including micro-cracks in welds and uneven coating thickness) specific to MS01-03’s diverse part geometries. The system learns from production data to reduce false rejects by 15% over time, ensuring high yield rates even when switching between part types.

- Minimum Order Quantity: 1,000 pieces for standard MS01-03 configurations; for custom material/finish combinations, MOQ is 1,500 pieces (lower than industry average 2,000 pieces for multi-variant models). Custom orders include a “feasibility matrix” that outlines cost implications of modifications (e.g., switching to 316L adds 12% to unit cost) to help clients balance needs and budget.

-

Adaptive Design Support: Our engineering team provides “variant-friendly” design support for MS01-03, including a library of pre-approved modifications (e.g., standard hole patterns, edge treatments) that reduce design time by 40%. For example, a client needing MS01-03 for both oven door latches and microwave chassis can reuse 70% of the base design, only adjusting material and mounting features.

-

Modular Production Flexibility: Unlike fixed-process models, MS01-03’s stamping and drawing processes can be reconfigured to produce 10+ part types (from flat plates to deep-drawn enclosures) on the same line. This eliminates the need for clients to source multiple models for different components—reducing inventory costs by 25% on average.

-

Targeted Durability for Diverse Use Cases: MS01-03’s material-structural pairing is optimized for specific applications: 316L stainless steel variants include reinforced edges for medical equipment (withstanding frequent cleaning); 5052 aluminum variants feature ribbed structures for communication chassis (enhancing heat dissipation); and carbon steel variants undergo quenching (HRC 40-45) for industrial conveyor parts (resisting wear from friction).

-

Rapid Adaptation to Changes: MS01-03’s modular mold design allows for quick adjustments—e.g., resizing a part’s length by 10mm takes 1 week instead of 4 weeks. This is critical for clients responding to design revisions, such as a white goods manufacturer updating a refrigerator’s internal layout.

-

Cost Efficiency for Multi-Variant Orders: MS01-03’s shared production line reduces setup costs for multi-part orders. Clients ordering 3+ MS01-03 variants (e.g., different material brackets for the same automotive model) receive a 10% bundle discount—making it more affordable than sourcing separate models.

-

Comprehensive Environmental Testing: Beyond standard quality checks, MS01-03 undergoes application-specific environmental testing: UV exposure testing (1,000 hours) for outdoor parts, humidity cycling (-40°C to 85°C, 500 cycles) for electronic enclosures, and chemical resistance testing (to detergents, oils, and solvents) for commercial kitchen parts—ensuring performance in real-world conditions.

- Simplified Customization: MS01-03’s “customization menu” streamlines modification requests: clients select base material, thickness (0.5-3.0mm), surface treatment, and key dimensions (with pre-approved ranges), reducing lead time for custom orders by 30% compared to fully bespoke models.

-

White Goods: MS01-03 serves as multi-purpose components: 0.8mm galvanized steel variants for microwave door hinges (corrosion-resistant to kitchen steam), 1.5mm 5052 aluminum variants for air conditioner fan shrouds (lightweight for energy efficiency), and 2.0mm SPCC carbon steel variants for oven inner brackets (heat-resistant up to 180°C). Its dimensional consistency ensures compatibility with OEM assembly robots, reducing manual adjustments.

-

Automotive Parts: Focuses on interior and non-exposed components: 1.2mm 316L stainless steel variants for door handle mounting plates (resisting sweat corrosion), 2.5mm galvanized steel variants for seat frame brackets (load-bearing 80kg+), and 1.0mm matte-coated variants for dashboard trim supports (matching interior finish). It meets automotive interior standards for VOC emissions (≤ 10μgC/g).

-

Commercial Equipment: Excels in high-use, harsh environments: 3.0mm galvanized steel variants for commercial refrigerator door hinges (supporting 25kg+ door weight), 1.8mm electropolished 316L variants for food processing machine guards (FDA-compliant), and 2.2mm UV-resistant powder-coated variants for outdoor vending machine panels (withstanding 5 years of sun exposure without fading).

-

Industrial Sector: Addresses structural and functional needs: 2.8mm quenched carbon steel variants for conveyor track brackets (resisting wear from 10,000+ cycles), 1.0mm 5052 aluminum variants for sensor enclosures (lightweight for mobile equipment), and 1.5mm conductive-coated variants for industrial control panel chassis (EMI shielding for sensitive electronics).

- Other Industries: Adapts to niche requirements: 0.5mm 5052 aluminum variants for LED light fixture housings (heat-dissipating), 1.2mm nickel-plated variants for printer paper path guides (smooth surface reducing paper jams), and 2.0mm 316L variants for marine communication device brackets (saltwater corrosion-resistant). Its flexibility makes it a cost-effective choice for small-batch, specialized projects.

Welcome to our precision metal parts portfolio, where Model MS01-03 emerges as a versatile, high-adaptability solution engineered for diverse industrial demands—from heavy-duty mechanical applications to delicate electronic enclosures. Unlike specialized models limited to narrow use cases, MS01-03 is designed with a “broad-compatibility core” that retains strict precision while accommodating a wider range of material variants and structural geometries. Our dedicated design team collaborates closely with clients to tailor MS01-03 to unique requirements: whether it’s adjusting material thickness for industrial conveyor brackets or refining edge finishes for electronic device chassis, every modification aligns with the model’s inherent strength and production efficiency.

At the center of MS01-03’s value is its integration of advanced progressive stamping (with expanded capabilities) and adaptive metal drawing processes, paired with modular automated production lines. Unlike fixed-process models, MS01-03’s production setup can be reconfigured in 48 hours to switch between material types or adjust part dimensions—critical for clients with multiple project needs. For example, the progressive stamping dies for MS01-03 feature 14-18 adjustable stations, enabling it to produce both flat mounting plates (for office equipment) and complex curved brackets (for automotive interior components) without full mold overhauls. We deliver more than a part: for MS01-03, we provide a “flexible solution package” that includes design adaptability, rapid process switching, and consistent quality—making it ideal for white goods manufacturers with seasonal product lines, automotive suppliers requiring multi-component batches, and industrial equipment firms needing both structural and functional parts.

Model MS01-03 is optimized for versatility without compromising precision, with each parameter calibrated to support diverse applications while maintaining reliability. Below is a detailed breakdown of its key specifications, highlighting traits that set it apart from narrow-use models:

Model MS01-03 combines precision with adaptability, addressing industry challenges like rigid production processes, limited material options, and high customization costs:

Model MS01-03’s broad compatibility makes it a go-to solution across diverse sectors, with adaptations tailored to each industry’s unique demands:

Q: How long does mold development and sample production take?

A: Mold development takes 6 weeks, and sample delivery is completed within 45 days, ensuring a quick response to customer needs.

Q: What production process do you use?

A: We use progressive stamping dies combined with metal drawing processes for production, ensuring high efficiency, precision, and excellent consistency, particularly suitable for parts with complex geometries.

Q: Do you meet automotive industry quality standards?

A: Yes, we are certified under the IATF 16949 Quality Management System, fully complying with automotive industry quality requirements.

Q: What are the advantages of metal drawing process?

A: The metal drawing process can produce deep thin-walled parts while maintaining uniform wall thickness and excellent surface quality, making it particularly suitable for manufacturing housings and container-type parts.

Q: What industries do your production capabilities cover?

A: We can produce not only metal parts for household appliances but also precision metal parts for automotive components, including both stamped and drawn parts.

Q: Do you support multiple surface treatment options?

A: Yes, we offer various surface treatment options including galvanization, nickel plating, painting, electrophoretic coating, and passivation to meet different application needs.

Q: Is the minimum order quantity negotiable?

A: 1,000 pieces is our standard minimum order quantity. For long-term cooperation or special requirements, we can negotiate flexibly.

Ready to enhance your oven door hinge performance? Contact us now for free technical consultation and a quote! Our engineers and sales team are here to provide professional support.

Email: [email protected]

Tel: 86-15663457251

Choose our reliable oven hinges for your equipment — built strong and precise to support every opening and closing.

Note: This product holds an EU design patent, ensuring unique and proprietary design.