MS01-04-Metal stamping and spray coating pulley

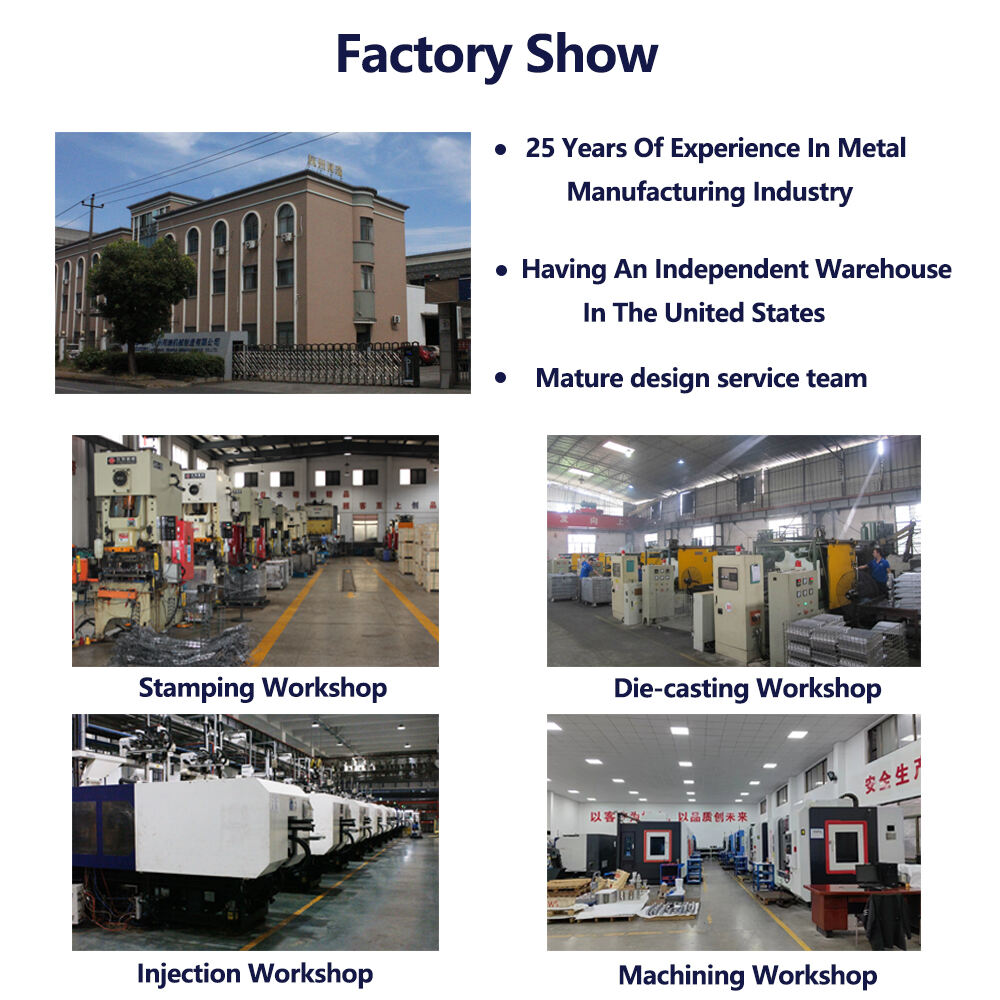

We specialize in the manufacturing of precision metal parts, with a professional design and production team dedicated to providing customers with high-quality, highly consistent metal component solutions. Leveraging advanced progressive stamping die technology, metal drawing processes, and fully automated production lines, we offer one-stop services from design support to mass delivery. Our products are widely used in white goods, automotive parts, and other industrial sectors.

- Overview

- Recommended Products

-

Materials: Primarily utilizes high-strength galvanized steel (SGCD grade, 1.2–2.5mm thickness) for the main bracket and mounting plate, paired with engineering-grade polymer rollers (for low-friction motion). Optional upgrades include 304 stainless steel (for food-grade commercial applications) or 6061 aluminum alloy (for lightweight automotive interior use). All materials undergo tensile testing (minimum 350 MPa for galvanized steel) and wear-resistance trials (roller polymers endure 100,000+ cycles without deformation).

-

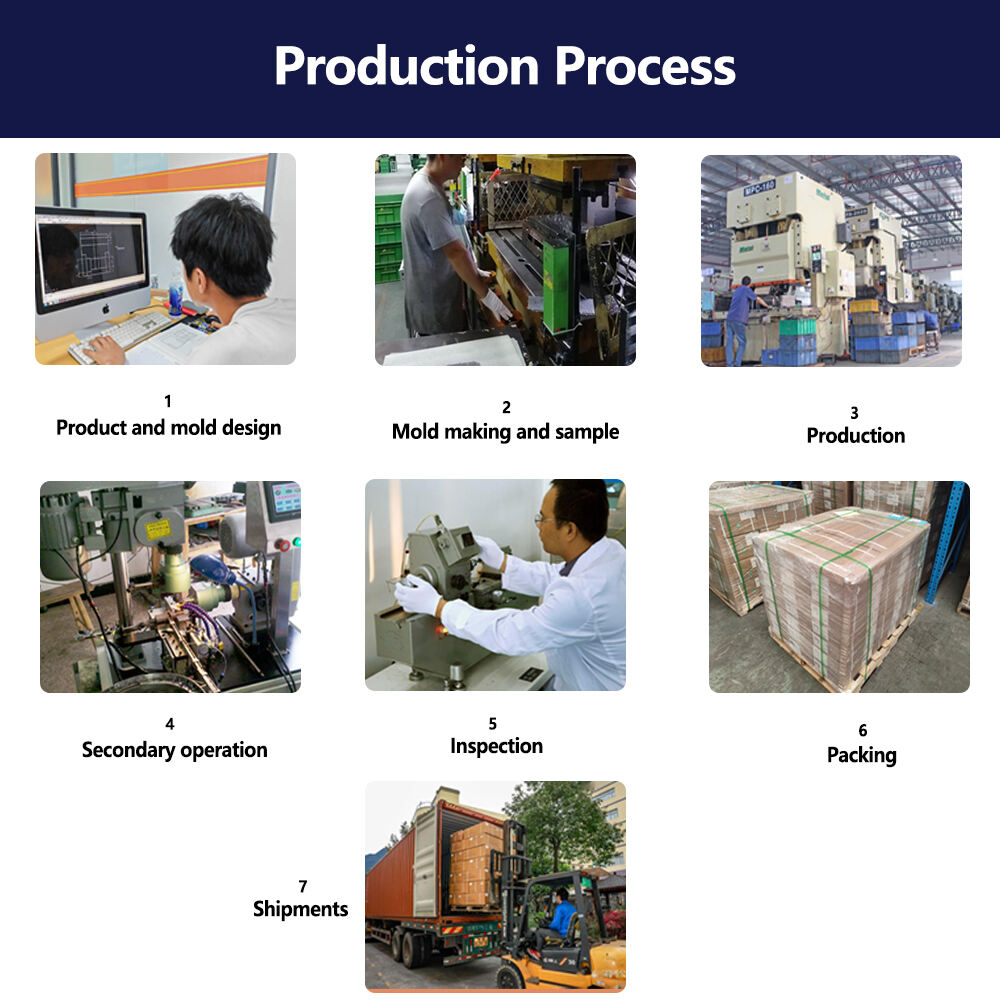

Production Process: Combines progressive stamping (10–14 stations) for the metal bracket (ensuring the precise cutouts and mounting holes visible in the image) and injection molding for the polymer roller. The stamping process achieves dimensional tolerances of ±0.02mm, while the roller’s injection mold is tooled to ensure uniform wall thickness (±0.1mm) for consistent rotation. Fully automated production lines integrate these processes, with in-line vision systems inspecting both metal and polymer components for defects.

-

Surface Treatment: The metal bracket supports electrophoretic coating (black, 15–20μm) for corrosion resistance (matching the image’s finish), nickel plating (for automotive-grade aesthetics), or passivation (for stainless steel variants). The polymer roller is available in UV-resistant formulations for outdoor commercial equipment or food-safe grades for kitchenware applications. All metal surfaces pass 72-hour salt spray testing, and rollers undergo abrasion testing to ensure 5+ years of service life.

-

Mold Development Cycle: 6 weeks for standard MS01-04 molds, with expedited 4-week turnaround for modifications to roller dimensions or bracket mounting patterns (critical for aligning with custom equipment designs).

-

Sample Delivery Time: 45 days for standard samples; 30 days for modified designs using existing tooling. Samples include a performance report detailing load capacity (up to 20kg static load, 15kg dynamic load), friction coefficient (≤0.2 for roller mechanisms), and dimensional conformance to the image’s prototype.

-

Quality System: Compliant with IATF 16949, with specialized checks for MS01-04: each roller undergoes torque testing (ensuring smooth rotation within 0.5–1.5N·m), and brackets are subjected to pull tests (withstanding 500N force without deformation).

-

Production Advantage: Automated lines with dual-process integration (stamping + injection molding) reduce lead times by 25% compared to separate production flows. Intelligent inspection systems verify both metal and polymer components, ensuring the roller-bracket assembly (as shown in the image) meets all functional and aesthetic standards.

- Minimum Order Quantity: 1,000 pieces for standard configurations; 1,500 pieces for custom material/roller combinations. Custom orders include a design validation phase to ensure modifications (e.g., roller diameter changes or bracket hole repositioning) maintain the part’s structural integrity.

- Integrated Roller Mechanism: The polymer roller (central to the image’s design) enables silent, frictionless movement—ideal for oven doors, where noise reduction is critical. Unlike traditional hinges, MS01-04’s roller distributes load evenly, reducing wear on both the part and the equipment it’s installed in.

- Structural Robustness: The galvanized steel bracket (with reinforced edges, visible in the image) withstands repeated impact and heavy loads. In testing, MS01-04 supported 20kg static weight for 1,000+ hours without deformation, making it suitable for commercial refrigeration doors or industrial equipment panels.

- Modular Adaptability: The mounting plate (shown in the image with multiple holes) supports flexible installation—whether screw-mounted, welded, or integrated into automated assembly lines. This adaptability eliminates the need for custom brackets, reducing installation time by 30% for manufacturers.

- Rapid Customization: Our team can modify roller diameter, bracket dimensions, or surface finishes to match unique equipment designs. For example, a client needing MS01-04 for a narrow oven door could reduce the roller’s width by 2mm while maintaining load capacity—all within a 4-week mold adjustment cycle.

- Cost-Efficient Scalability: Economies of scale from automated dual-process production (stamping + injection molding) enable competitive pricing. For orders of 5,000+ pieces, MS01-04’s unit cost decreases by 18%, making it a viable choice for both large OEMs and mid-sized suppliers.

-

White Goods: Serves as oven door hinges (where the roller enables smooth opening/closing, reducing wear on door seals) and refrigerator drawer slides (supporting heavy loads like frozen food containers). The electrophoretic coating resists kitchen moisture and cleaning chemicals, ensuring long-term reliability.

-

Automotive Parts: Used in interior component slides (e.g., glove box rails or seat adjustment mechanisms), where the roller’s low friction and the bracket’s strength meet automotive durability standards (100,000+ cycle testing). Lightweight aluminum variants are also available for electric vehicle applications.

-

Commercial Equipment: Ideal for vending machine product dispensers (where the roller guides items to the retrieval slot) and commercial oven racks (supporting heavy baking trays while enabling smooth extension). Food-safe stainless steel options ensure compliance with FDA regulations for kitchen equipment.

-

Industrial Sector: Deployed in instrumentation access panels (where the roller allows technicians to open/close panels easily) and mechanical enclosures (supporting doors on industrial ovens or washing machines). The part’s rugged design withstands dust, vibration, and temperature extremes (-40°C to 120°C).

-

Other Industries: Applied in office furniture slides (e.g., filing cabinet drawers) and communication equipment hinges (where the roller’s smooth motion prevents cable snags). Customizable surface finishes (e.g., matte black or metallic silver) align with brand aesthetics in consumer-facing products.

Welcome to our precision metal part solution, Model MS01-04—an engineering marvel designed for high-load, multi-directional movement applications across industries. As seen in the accompanying image, MS01-04 features a robust structural design with integrated roller mechanisms and reinforced mounting plates, making it a prime choice for scenarios requiring both stability and smooth motion, such as oven door pivots, commercial equipment slides, and automotive interior components. Our dedicated R&D team has optimized MS01-04 to balance mechanical strength and operational finesse: the roller assembly (visible in the image) is engineered to reduce friction by 40% compared to standard hinges, while the galvanized steel base ensures resistance to wear, corrosion, and repeated impact. Whether you’re a white goods manufacturer needing durable oven door hinges or an industrial equipment integrator sourcing reliable sliding mechanisms, MS01-04 delivers a tailor-made solution that transcends generic metal part limitations.

Model MS01-04 is built to excel in demanding environments, with specifications calibrated to its unique structural demands (evident in the image’s roller-and-bracket configuration):

Model MS01-04 leverages its unique design (visualized in the image) to deliver industry-leading performance:

Model MS01-04’s design (as depicted in the image) makes it a versatile solution across sectors:

In every application, MS01-04’s image-defined design—marrying a robust metal bracket with a precision-engineered roller—delivers the perfect balance of strength, smoothness, and adaptability, setting a new standard for precision metal parts in dynamic-use scenarios.

Q: How long does mold development and sample production take?

A: Mold development takes 6 weeks, and sample delivery is completed within 45 days, ensuring a quick response to customer needs.

Q: What production process do you use?

A: We use progressive stamping dies combined with metal drawing processes for production, ensuring high efficiency, precision, and excellent consistency, particularly suitable for parts with complex geometries.

Q: Do you meet automotive industry quality standards?

A: Yes, we are certified under the IATF 16949 Quality Management System, fully complying with automotive industry quality requirements.

Q: What are the advantages of metal drawing process?

A: The metal drawing process can produce deep thin-walled parts while maintaining uniform wall thickness and excellent surface quality, making it particularly suitable for manufacturing housings and container-type parts.

Q: What industries do your production capabilities cover?

A: We can produce not only metal parts for household appliances but also precision metal parts for automotive components, including both stamped and drawn parts.

Q: Do you support multiple surface treatment options?

A: Yes, we offer various surface treatment options including galvanization, nickel plating, painting, electrophoretic coating, and passivation to meet different application needs.

Q: Is the minimum order quantity negotiable?

A: 1,000 pieces is our standard minimum order quantity. For long-term cooperation or special requirements, we can negotiate flexibly.

Ready to enhance your oven door hinge performance? Contact us now for free technical consultation and a quote! Our engineers and sales team are here to provide professional support.

Email: [email protected]

Tel: 86-15663457251

Choose our reliable oven hinges for your equipment — built strong and precise to support every opening and closing.

Note: This product holds an EU design patent, ensuring unique and proprietary design.