Soft closing hinge

Welcome to our high-performance oven hinge solutions, where exceptional durability meets precision engineering. Designed for frequent use and everyday kitchen environments, our oven hinges ensure smooth, safe, and long-lasting operation of oven doors. Whether you are a home appliance manufacturer, after-sales service provider, or commercial kitchen equipment integrator, our hinges are the ideal choice for ensuring device reliability and user experience.

- Overview

- Recommended Products

-

Material: Crafted from high-quality galvanized steel sheet, selected for its exceptional tensile strength, impact resistance, and ability to withstand the temperature fluctuations (from 20°C to 200°C+) that oven components endure. The galvanized layer acts as a primary barrier against moisture and corrosion, while the steel’s rigidity ensures the hinge maintains its structural integrity—critical for supporting the soft closing mechanism’s consistent operation. Unlike thin-gauge steel used in budget hinges, our galvanized steel prevents warping or bending, which could disrupt the damping system’s performance over time.

-

Surface Treatment: To enhance both durability and aesthetic appeal, we offer three specialized surface treatment options, each tailored to complement soft closing functionality. Zinc plating adds an extra layer of corrosion resistance, ideal for humid kitchen environments where moisture could affect the hinge’s moving parts; nickel plating delivers a sleek, fingerprint-resistant finish that matches stainless steel ovens (a popular choice for premium residential kitchens); and anti-rust paint provides a scratch-resistant coating that protects the hinge from accidental bumps with cookware—ensuring the soft closing mechanism’s components remain free from debris or damage. All treatments are tested to resist flaking or fading, even after prolonged exposure to heat and cleaning chemicals.

-

Load Capacity: Our soft closing hinge models support door weights ranging from 5kg to 15kg, with each model’s damping system calibrated to match specific weight ranges. For compact countertop ovens (5-8kg door weight), the soft closing mechanism is tuned for a lighter, quicker yet gentle close; for larger built-in or commercial ovens (10-15kg door weight), the damping system is reinforced to handle heavier loads without compromising the soft closing motion. This weight-specific calibration ensures that regardless of the oven size, the hinge closes at a consistent speed—approximately 2-3 seconds from 45° to fully closed—preventing both slow, inefficient closing and sudden lurching.

-

Opening Angle & Soft Closing Range: Featuring a multi-gear adjustment design, the hinges allow oven doors to stay open at 45°, 90°, and 135° angles (custom angles available upon request). The soft closing function activates automatically when the door is lowered to 45°—a range selected to balance convenience (allowing users to place/remove dishes without the door closing prematurely) and safety (ensuring the door doesn’t stay partially open, wasting heat). The damping mechanism controls the door’s descent from 45° to 0°, ensuring it never closes faster than 0.5 inches per second—slow enough to prevent slamming, but fast enough to avoid disrupting workflow in commercial settings.

-

Installation Methods: We provide three flexible installation structures, each designed to simplify assembly while preserving soft closing functionality. Screw fixation is ideal for after-sales upgrades, as it allows easy removal (critical for servicing the damping mechanism if needed); welded installation offers maximum structural stability for heavy-duty commercial ovens, ensuring the hinge’s alignment (vital for consistent soft closing) remains intact; and quick-install structures (with snap-on brackets) reduce assembly time by up to 50% for manufacturing lines, with pre-aligned holes that guarantee the damping system is positioned correctly. Each method includes a calibration guide to ensure the soft closing motion is optimized post-installation.

-

Compatibility: Our soft closing hinges are engineered to fit a wide range of oven types, extending beyond standard household models. They are compatible with built-in ovens (both single and double-door designs), countertop ovens (including toaster ovens with larger doors), and commercial baking equipment such as small pizza ovens and convection ovens. Notably, they can also be retrofitted to most existing ovens (from brands like LG, Electrolux, and Kenmore) with minimal modifications—making them a popular choice for after-sales upgrades. The damping mechanism’s compact design ensures it fits within standard hinge mounting spaces, eliminating the need for custom cabinet adjustments.

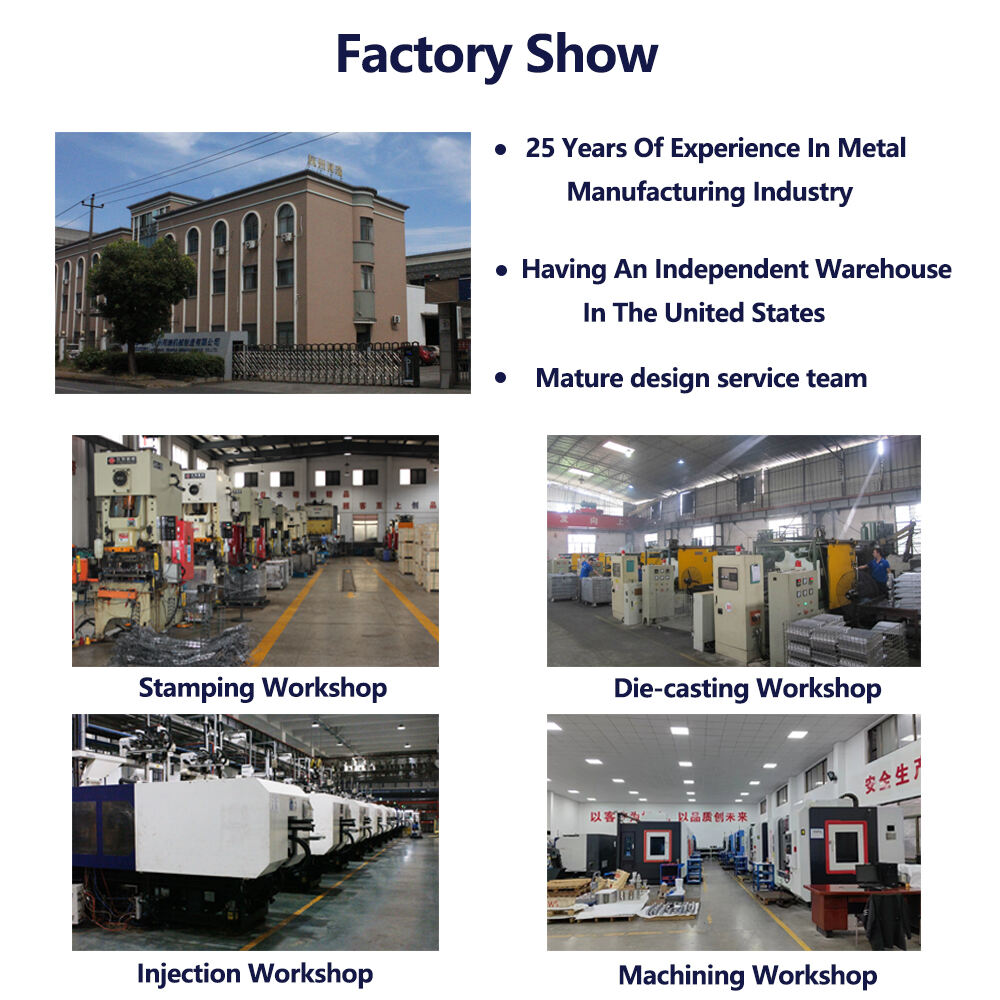

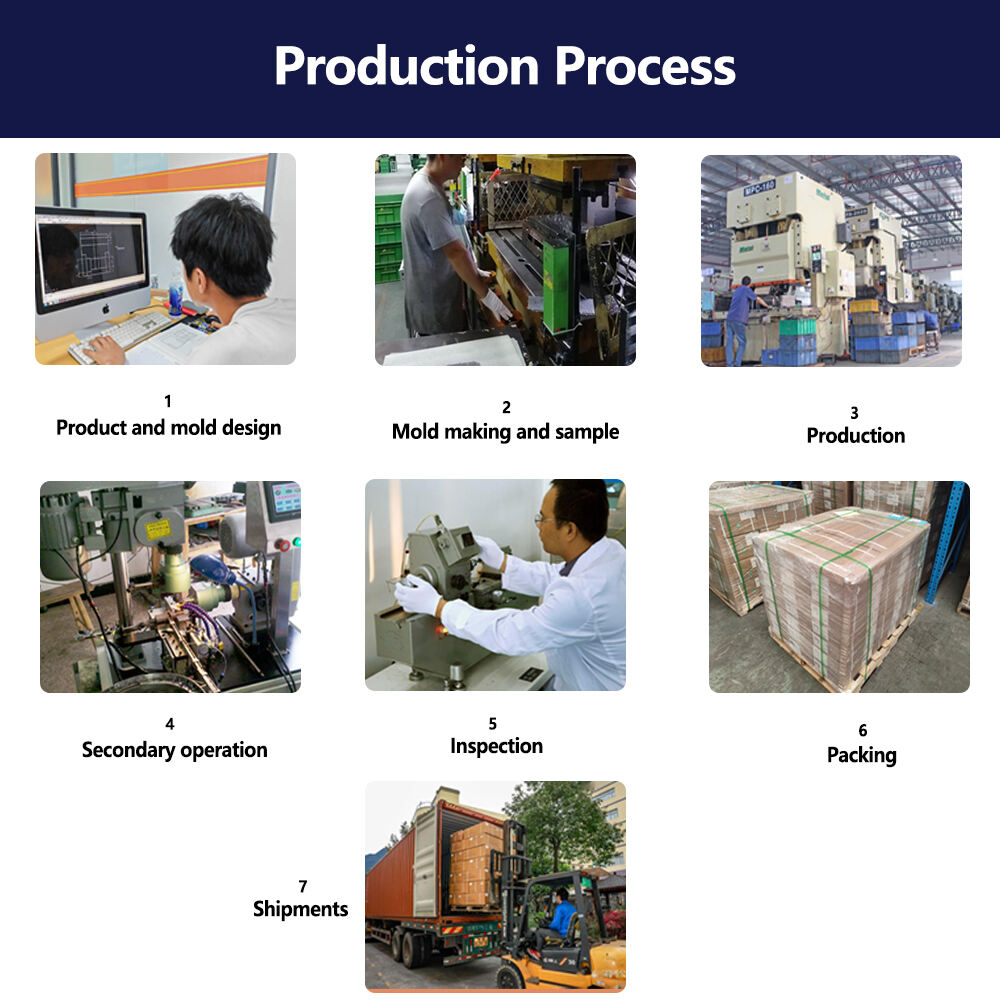

- Production Process: We leverage a fully automated assembly line with specialized stations for integrating the soft closing mechanism. Precision robotics handle the delicate installation of the damping system (whether hydraulic or spring-assisted), ensuring each component is aligned to within 0.1mm—critical for consistent soft closing performance. Real-time sensors test the soft closing speed of every hinge during production, rejecting any unit that doesn’t meet the 2-3 second closing standard. This automated process reduces production lead times by 30% compared to manual assembly, while also ensuring that the soft closing function remains reliable for the hinge’s entire lifespan.

-

Gentle Soft Closing Function: The core feature—an integrated damping system—ensures oven doors close slowly and quietly, eliminating slamming noises (which can reach 60+ decibels with standard hinges) and reducing noise pollution in kitchens. This is especially valuable in open-concept residential kitchens (where oven noise can disrupt conversations) and commercial spaces like cafes (where a quiet environment enhances customer experience). The soft closing motion also protects oven door seals from wear and tear, extending their lifespan by up to 50% compared to standard hinges.

-

Durable & Corrosion-Resistant: The high-quality galvanized steel base, paired with premium surface treatments, creates a dual defense against oxidation and corrosion—critical for the hinge’s moving parts (including the soft closing mechanism). In third-party testing, our hinges withstood 600 hours of salt spray exposure (100 hours more than industry standards for standard hinges) without showing signs of rust or reduced soft closing performance. The damping mechanism’s components are also sealed to prevent dust or liquid ingress, ensuring consistent operation even in messy commercial kitchens.

-

Safe & Injury-Proof: The soft closing function eliminates the risk of accidental finger pinching—one of the most common kitchen injuries related to oven use. By controlling the door’s descent to a gentle speed, the hinge ensures that even if a child’s hand is near the door edge, there is time to move it before closing. Additionally, the hinge’s load-bearing design prevents door sagging (which can cause the soft closing mechanism to misalign), while a built-in stop at 45° prevents the door from closing accidentally while users are loading/unloading dishes.

-

Long-Lasting Soft Closing Performance: Every hinge undergoes rigorous fatigue testing specifically for the soft closing mechanism—simulating 100,000 opening-and-closing cycles (equivalent to 15+ years of residential use). The damping system’s components (such as hydraulic seals or spring coils) are made from high-grade materials (like nitrile rubber for seals) that resist wear, ensuring the soft closing speed remains consistent over time. Unlike budget soft closing hinges that lose their damping effect after 20,000 cycles, our hinges maintain their gentle closing motion for the entirety of their lifespan.

-

Flexible Adjustment: The multi-gear opening angle design allows users to adapt the oven door to their needs—45° for quick ingredient checks, 90° for full access, and 135° for large dishes—while the soft closing function remains active regardless of the opening angle. For custom oven designs (such as under-counter models with limited clearance), we offer adjustable soft closing activation points (e.g., activating at 30° instead of 45°) to ensure the mechanism works seamlessly with unique installation constraints.

- Easy Installation & Maintenance: Standardized interfaces mean our soft closing hinges fit most major oven brands, with detailed installation guides that include step-by-step instructions for calibrating the soft closing mechanism (e.g., adjusting the damping screw to fine-tune closing speed). The screw fixation option allows for easy removal—so if the damping system needs cleaning (to remove dust that could affect performance), it can be done in minutes. We also include a maintenance kit with each bulk order, containing lubricant for the hinge’s moving parts and replacement O-rings for the damping mechanism (if needed).

- Home Appliances: In residential kitchens, our hinges are a popular upgrade for built-in ovens (where their quiet operation complements open-concept living spaces) and countertop ovens (used frequently by busy parents and small families). For households with young children, the soft closing function provides peace of mind by eliminating finger-pinching risks. Additionally, in luxury homes where high-end appliances are a focal point, the hinges’ nickel-plated finish and smooth operation add a premium touch that aligns with upscale kitchen designs.

- Commercial Kitchens: In commercial settings like cafes, bakeries, and boutique restaurants—where noise reduction is key to customer satisfaction—our soft closing hinges transform the clatter of standard oven doors into a quiet, unobtrusive action. For example, in a cafe with an open kitchen, patrons won’t be distracted by the sound of oven doors slamming, while staff benefit from the hinge’s durable design (supporting 10-15kg commercial oven doors) and consistent soft closing performance. Warming cabinets, which are opened and closed frequently to serve food, also benefit from the hinges’ gentle motion, preventing heat loss from abrupt closing.

- Specialized Residential Settings: Our hinges are ideal for specialized home environments, such as kitchens in assisted living facilities or homes with elderly residents. The soft closing function eliminates the need for force to close the oven door (a challenge for those with limited hand strength) and reduces the risk of injury. Additionally, in apartments where thin walls amplify noise, the hinges’ quiet operation prevents disturbances to neighbors—making them a thoughtful choice for multi-unit dwellings.

- After-Sales Upgrades: For after-sales service providers, our soft closing hinges are a high-value upgrade option for customers looking to improve their existing ovens. Many homeowners are unaware that standard hinges can be replaced with soft closing models, and our hinges’ compatibility with most brands makes this upgrade accessible. For example, a service technician can replace a customer’s old, noisy hinges with our soft closing version in under an hour—immediately improving the oven’s usability and safety. This upgrade not only increases customer satisfaction but also allows service providers to offer a premium service that differentiates them from competitors.

Welcome to our premium soft closing oven hinge solutions—where the core benefits of exceptional durability and precision engineering are elevated by an innovative soft closing mechanism. Unlike standard oven hinges that rely on basic mechanical operation, our soft closing hinges integrate a hydraulic or spring-assisted damping system, designed to eliminate the harsh “slamming” of oven doors and replace it with a gentle, controlled closing motion. In modern kitchens—whether residential spaces where families gather or busy commercial settings like cafes and bakeries—oven doors are opened and closed dozens of times daily; our soft closing hinges transform this routine action into a quiet, smooth experience that protects both the oven door and the user.

What sets our soft closing hinges apart is their ability to balance robust performance with user-centric comfort. We recognize that a standard hinge’s abrupt closing can cause damage to oven door seals over time (compromising heat retention and energy efficiency) or even lead to accidental finger pinching—risks that are entirely eliminated by our soft closing design. Every component, from the damping mechanism to the structural steel, is engineered to meet the demands of frequent use while delivering consistent soft closing performance. Whether you’re a home appliance manufacturer aiming to add a premium touch to your mid-to-high-end oven lines, an after-sales service provider seeking to upgrade customers’ existing ovens with safer, quieter hinges, or a commercial kitchen integrator outfitting spaces where noise reduction is critical (such as open-concept cafes), our soft closing hinges are the ideal choice. They don’t just fit ovens—they redefine the user experience by turning a functional action into a refined, worry-free moment.

Our soft closing oven hinges are designed to combine versatility, precision, and the unique benefits of soft closing technology. Here’s a detailed breakdown of their key specifications, each optimized to enhance both performance and user comfort:

To ensure cost-effectiveness in producing the specialized soft closing components (such as the damping cylinders or springs), we have set a Minimum Order Quantity (MOQ) of 500 pieces per order. This MOQ allows us to source high-quality damping materials in bulk (reducing per-unit costs) and streamline the automated assembly process (minimizing setup time for the soft closing mechanism stations). For bulk orders exceeding 2,000 pieces, we offer additional benefits tailored to soft closing technology: customized damping speed calibration (to match specific oven door weights), branded damping mechanism covers (with your logo), and priority technical support for installation troubleshooting. We also assign a dedicated engineer to bulk clients to ensure the soft closing function meets their exact requirements.

Our soft closing oven hinges combine all the benefits of standard high-performance hinges with the unique advantages of soft closing technology, addressing pain points that standard hinges cannot:

Our soft closing oven hinges are designed to enhance user experience across residential, commercial, and specialized settings, leveraging their unique soft closing technology to address specific needs:

Q: What is the lead time for custom hinge orders?

A: Standard orders take 6–10 weeks. Thanks to our automated production line, some standard models can be shortened to 5 weeks. Expedited orders are negotiable.

Q: Are the hinges suitable for high-frequency use in intensive environments?

A: Yes. Our hinges undergo rigorous fatigue testing and can withstand tens of thousands of openings and closings, making them ideal for commercial applications.

Q: Can the opening angle be customized?

A: Absolutely. We offer multi-gear adjustment designs and can provide customized opening angles based on your specific needs.

Q: Are special tools or skills required for installation?

A: Most models are designed for standardized installation and can be fitted using common tools. We also provide detailed installation instructions.

Q: How is corrosion resistance ensured?

A: We use galvanized steel sheets combined with multi-layer surface treatments to effectively resist moisture and daily cleaning agents in kitchen environments.

Q: Do you provide samples for testing?

A: Yes, we offer a limited number of samples to qualified customers for testing and validation. Please contact our sales team for specific policies.

Ready to enhance your oven door hinge performance? Contact us now for free technical consultation and a quote! Our engineers and sales team are here to provide professional support.

Email: [email protected]

Tel: 86-15663457251

Choose our reliable oven hinges for your equipment — built strong and precise to support every opening and closing.

Note: This product holds an EU design patent, ensuring unique and proprietary design.